The Importance of Blockchain in a Post-Pandemic World

The Importance of Blockchain in a Post-Pandemic World

The Importance of Blockchain in a Post-Pandemic World

22 Juni 2020

Aptean Staff Writer

Aptean Staff Writer

If food safety was one of the most important topics in the food industry pre-pandemic, it has now been catapulted to the highest critical level of importance. The global pandemic has brought to light issues with the way the international supply chain operates – from food shortages to worker health to the importing and exporting of goods – and as we finally emerge from months-long lockdowns and social isolation, it’s crucial that the food industry look inward to help avoid the effects of another devastating pandemic in the future.

One of the industry’s newest and most promising advances in recent years, blockchain technology, will undoubtedly play a key role not only in the safety of our food post-pandemic, but also in the way the world works to help mitigate supply chain challenges during times of global chaos and hardship.

In this blog, we discuss the importance of blockchain as a tool in ensuring post-pandemic food safety, the role it’ll play in the security of global supply chains going forward and the ways it integrates with an enterprise resource planning (ERP) system to promote full end-to-end traceability.

What is Blockchain?

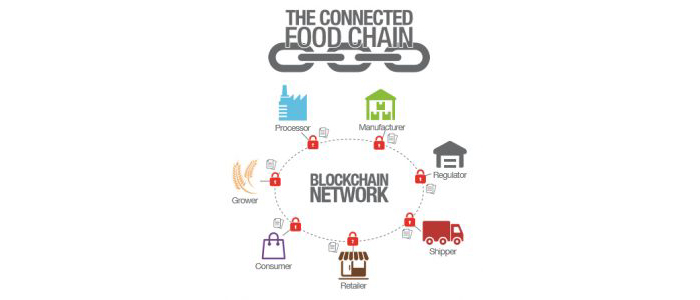

Blockchain technology is a way of storing and sharing information across a network of stakeholders in a virtual space. Blockchain is an example of a distributed ledger technology (DLT), meaning that data is distributed and stored in many places, rather than in one centralized system. This means that no single stakeholder owns the system and the data, which makes it virtually tamper-proof and helps to create a space of ultimate transparency and security.

While blockchain wasn’t created specifically for the food industry, because the technology was developed to help manage a chain of actions and consequential transactions, it lends itself well to connecting the chain of transactions present in the food manufacturing process. In the fresh produce industry, for example, the supply chain may consist of producers, processors, trading companies and retailers. Blockchain technology makes every single transaction throughout the chain available to all these stakeholders, helping to ensure self-regulation and enhanced traceability.

The Future of Food Safety

In April 2019, the U.S. Food and Drug Administration (FDA) announced a new approach to food safety that focuses on leveraging technology and other tools to create a more digital, traceable and safer food system. Part of this “New Era of Smarter Food Safety” includes the use of blockchain technology to promote the role of food safety culture on farms and in facilities across the U.S.

A major factor in the FDA’s push for the use of blockchain in promoting a greater sense of food safety and traceability is around the idea of chain-of-custody and accountability.

Here’s an example of how product moves through the supply chain without blockchain technology in place:

Farmers harvest crops based on agriculture standards and guidelines

Produce is shipped by a carrier to a distribution center or manufacturing plant based on temperature monitoring and traceability guidelines

Product is handled, processed, broken down, etc., at a plant according to food safety standards and tracked at the case or item-level

Shippers move product to restaurants, retail outlets, distribution centers, foodservice channels, etc. based on temperature monitoring and sanitization standards

In this example, multiple handoffs occur as product moves through the supply chain with no documentation linking each stage together. While each stakeholder does its best to follow food safety guidelines and standards, what did or did not happen in terms of safety regulations and protocols is impossible to track. The chain-of-custody in terms of food safety disappears, and now all players are responsible if an issue occurs.

With blockchain technology, each supply chain transition point can be thought of as a “contract” between all members of the chain. In the example above, the farmer in the first step of the supply chain may have to provide soil hazard testing data in order to fulfill her part of the contract. At the third stage, processing line testing or specific quality checks may have to be logged prior to passing the product along for distribution.

Blockchain, then, creates a real-time view of the journey of an item or ingredient throughout the supply chain. By integrating the financial, traceability and food safety data into a single blockchain, it’s easy to see where an issue may have occurred and who is responsible.

Let’s take a look at Walmart’s use of blockchain to track the origins of mangoes being sold across stores in the U.S. as an example. In 2019, Walmart tested a proof-of-concept project aimed at introducing blockchain technology into its supply chains. The results were indisputable: by utilizing blockchain, the time needed to trace a mango through Walmart’s supply chain had dropped from seven days to 2.2 seconds.

The coronavirus pandemic has revealed weaknesses within the food industry. The unpreparedness of many food companies in terms of raw material sourcing, supply chain communication and overall food safety practices has become increasingly evident as more and more of the world’s supply chains and markets are forced to shut down amidst large-scale outbreaks and government-mandated lockdowns.

Though viruses like the coronavirus aren’t typically spread through contaminated food, research does show that it can remain viable on surfaces for up to 72 hours. With so much still unknown about how the coronavirus is transmitted and what the food industry will look like post-pandemic, it’s critical that we utilize new technology to promote more seamless communication and information sharing in order to keep our food safe.

Mitigating Pandemic-Related Food Supply Challenges

As the Coronavirus pandemic continues to wreak havoc on global supply chains, some of the world’s largest companies are utilizing blockchain to lessen the severity of various food supply challenges. In April 2020, for example, Cargill and Agrocrop, two of the biggest players in the agri-food industry, teamed up to pilot blockchain for use in cross-continental commodity trading.

The pilot initially focused on the trading of wheat from North America to Southeast Asia and was completed in five days, whereas traditional trading processes can take up to a month to settle. This demonstrates the power of partnerships and blockchain technology to ensure that the global agriculture supply chain is able to deliver fresh food where it is needed during times of uncertainty.

But in order to truly understand the effects of the pandemic on global supply chains, let’s take a look at the U.S. meat industry as another example. In the last month, outbreaks at three of the country’s largest pork processing plants resulted in complete shutdowns. These plants account for 15% of all national production, making it extremely difficult for retailers looking to supplement this shortfall to find alternative facilities. Once these alternatives are found, the process of exchanging and validating appropriate quality certifications and requirements creates even further delays and subsequent shortages. On the flip side, farmers who relied on these plants to process their meat are also struggling to find new partnerships as their expenses and herds grow, and the US’s ability to harvest pork drops by 40%. Again, once alternative processors are found, USDA and quality certifications need to be exchanged and validated.

So how can blockchain technology help? Blockchain creates a streamlined certification sharing process for the farmers, processors and retailers involved. Documents like certifications can be stored, tracked and shared easily through the network, ensuring that any disruptions to the supply chain are mitigated and businesses can continue producing product for consumers. In terms of food safety, in high-risk environments it can be easy to justify a missing certificate or the absence of compliance paperwork. Having documents stored and accessible to a network of global food supply chain members helps speed up the process of certification sharing and collaboration.

In order to fully acknowledge the role blockchain will play in reducing food supply challenges post-pandemic, it’s essential to look at the technology in terms of its contribution to food safety as well. Companies like Walmart, for example, mandated the use of blockchain for all of its suppliers of fresh, leafy greens following a major U.S.-based E. coli outbreak that sickened hundreds of consumers and killed five. Similar to the fallout following this deadly outbreak, safety and traceability standards during the coronavirus pandemic continue to shift and be tested. In order to ensure compliance and the health of consumers, it’s imperative that businesses are able to effectively track the provenance of their products and ingredients.

Blockchain and ERP

As more and more emphasis is put on utilizing blockchain technology to enhance food traceability measures amidst the coronavirus pandemic, ERP software providers are developing the capability for blockchain integration to increase the traceability functionality inherent to most food-specific ERP solutions.

Aptean’s food and beverage solutions utilize blockchain middleware to provide users with one interface that brings together various interrelated instances and elements of blockchain data. This integration enables users to securely share their traceability data throughout the supply chain.

In order to ensure the safety of our food supply post-pandemic, it is essential that the food industry do what it can to prepare for the future. As traceability and product tracking become increasingly essential to all parts of the supply chain, blockchain has emerged as a solution to improve the industry’s tracking capability. This ability to track and increase communication between members of the supply chain will undoubtedly lead to enhanced food safety measures and the ability to mitigate supply chain risks during times of global uncertainty.

To learn more about Aptean’s food and beverage solutions, reach out to us. We love to talk.

Sind Sie bereit, Ihr Unternehmen grundlegend zu verändern?

Wir bieten Ihnen die spezialisierten ERP-Lösungen, die Sie für die Herausforderungen Ihrer Branche benötigen.