Featured in this post

How Life Sciences Document Management Drives Compliance and Reduces Risk

Share

How Life Sciences Document Management Drives Compliance and Reduces Risk

28 Aug 2025

Steve Reynolds | Senior Product Manager

Steve Reynolds | Senior Product ManagerBlog Post

Short on Time? Here’s an At-A-Glance Summary

Why it matters: Even one missing record can cause recalls, fines or reputational harm. Strong documentation helps protect consumers and keep regulators satisfied.

Regulations to watch: FDA 21 CFR Part 111, MoCRA and Health Canada rules require precise, verifiable records across supplements and cosmetics

Core documents you can’t skip: CoAs, SDSs, MMRs and BPRs prove quality and traceability, making audits faster and recalls less likely.

Best practices to follow: Vet suppliers thoroughly, tighten your in-house processes and implement an ERP system to centralize documents, streamline approvals and provide real-time visibility into compliance.

In highly-regulated industries like dietary supplements, nutraceuticals and cosmetics, life sciences document management is more than a back-office responsibility; it’s a cornerstone of operational excellence, compliance and brand trust. Whether it's passing an FDA inspection, launching a new product or managing a recall, success hinges on how well your documents are organized, accessible and traceable.

This article, based on our ERP Perspectives podcast series, explores why life sciences companies must treat document management as a strategic function. We’ll cover the types of documents that are critical for regulatory compliance, and how life sciences ERP systems with built-in compliance features can streamline safety data sheet management, batch documentation and audit readiness.

Why Document Management Is Critical in Life Sciences

In life sciences, the stakes are higher. Products like dietary supplements, nutraceuticals and cosmetics can have a direct impact on consumer health and safety. A documentation error like a missing certificate of analysis (CoA) or an outdated safety data sheet (SDS) can lead to serious consequences such as adverse health events, regulatory enforcement actions, costly recalls and lasting reputational damage.

Compliance with regulations like FDA 21 CFR Part 111, ISO 22716 and the Modernization of Cosmetics Regulation Act (MoCRA) requires meticulous documentation. Manufacturers must maintain records that prove every step of production meets quality, safety and labeling standards.

But compliance is only one part of the story. Effective document management also supports faster audits, traceability during investigations and stronger internal collaboration. It enables your teams to make informed decisions and respond quickly when deviations occur, ultimately safeguarding both consumers and your brand.

Key Documents Required for Compliance

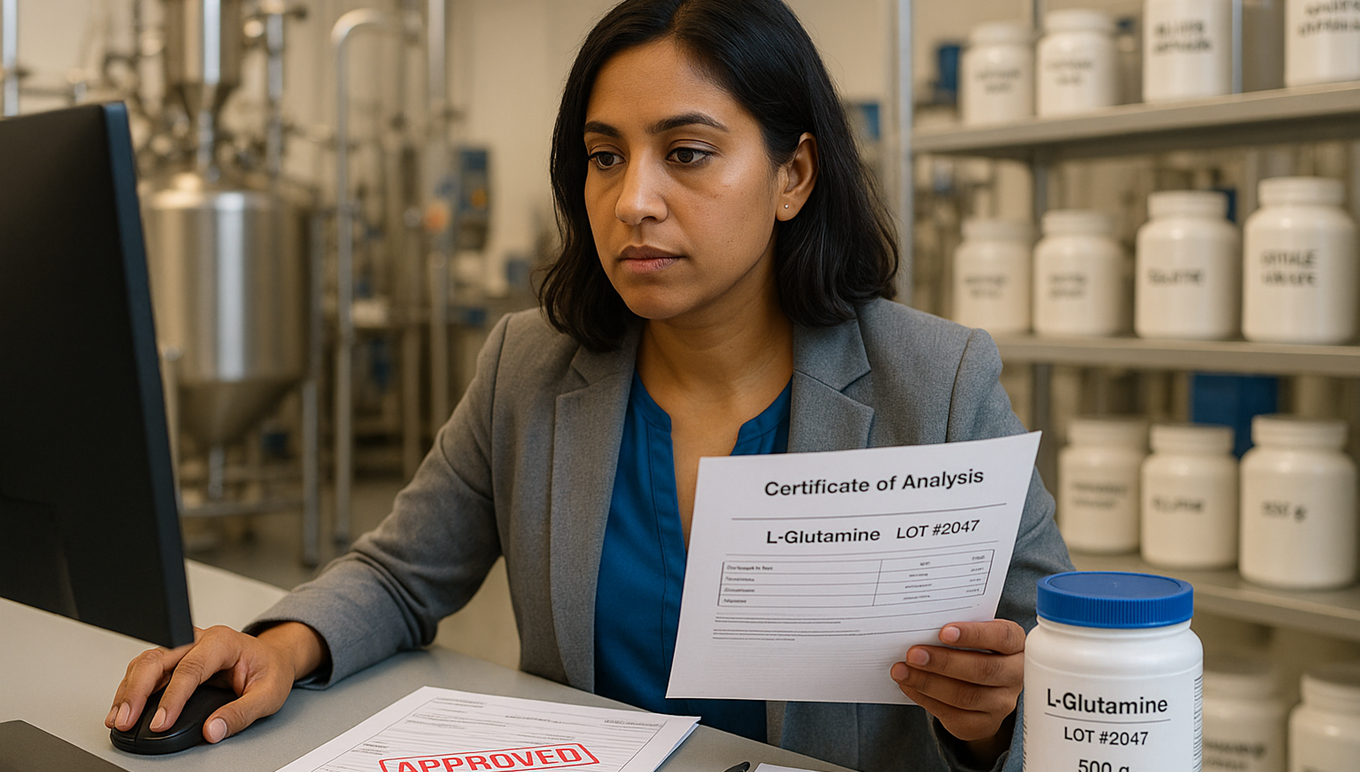

Certificate of Analysis (CoA)

A CoA is a formal quality assurance document that confirms a batch or lot of a raw material or finished product meets defined specifications for identity, purity, strength and composition.

For dietary supplements regulated under the FDA’s 21 CFR Part 111, CoAs are mandatory at two critical control points: raw materials entering production and finished products before distribution. Suppliers typically provide raw material CoAs, but it's crucial for manufacturers to independently verify these results to ensure compliance and consumer safety.

Cosmetics, though historically less regulated in the U.S., now face stricter oversight thanks to MoCRA, making CoAs an industry-standard best practice for verifying safety and quality, even when not explicitly mandated.

Safety Data Sheet (SDS)

Safety data sheets focus primarily on occupational safety, outlining chemical hazards, safe handling procedures and emergency response instructions. For ingredients like solvents, preservatives and concentrated botanical extracts, SDS management is essential to protect workers and comply with OSHA and WHMIS standards. A centralized SDS repository ensures documentation is accessible, version-controlled and tied to inventory and production data.

Master Manufacturing Record (MMR)

The master manufacturing record, sometimes referred to as a master formula record (MFR), serves as the comprehensive recipe and blueprint for manufacturing each product. It includes detailed instructions for ingredients, quantities, processing parameters, quality checks and packaging guidelines, ensuring that products are produced consistently and safely.

Under 21 CFR Part 111, the FDA explicitly requires that an MMR exist for every dietary supplement formulation and batch size. Cosmetics manufacturers, though not yet mandated explicitly, follow equivalent rigorous documentation guided by ISO 22716 standards, a model MoCRA is expected to adopt.

Batch Production Record (BPR)

The BPR captures the actual execution of a manufacturing run, including materials used, operator signatures, test results and deviations. It’s critical to proving adherence to manufacturing standards and traceability, particularly in the event of an audit, recall or complaint investigation.

Best Practices for Managing Compliance Documentation

Companies with robust document management systems see fewer delays during inspections, improved operational agility and stronger customer confidence. For example, tying BPRs to production lots in a software system helps QA teams quickly trace and isolate potential issues. In a similar vein, managing safety data sheets digitally allows production teams to instantly access hazard information, reducing risks on the manufacturing floor. On the other hand, poor compliance documentation practices lead to significant consequences, including costly recalls, regulatory enforcement actions, financial losses and reputational harm. It’s clear then that strong life sciences documentation can mean the difference between smooth operations and costly setbacks. But knowing it matters is only half the battle—the real question is how to put the right practices in place. Here are some proven strategies to guide the way.

Apply Thorough Supplier Qualification

Robust supplier qualification ensures compliance documentation like CoAs and SDSs from suppliers is accurate and reliable. You should independently verify suppliers’ quality systems, documentation authenticity and test results, preventing costly compliance missteps.

Create Detailed In-House Documentation Management Processes

Effective internal documentation involves clearly defined MMRs and thorough, accurate BPRs. You must ensure your documentation is always clear, controlled and complete, with rigorous processes for approvals, updates and periodic reviews to ensure compliance and operational efficiency.

Implement Life Sciences ERP Systems

A modern enterprise resource planning (ERP) system can play a pivotal role in streamlining compliance documentation management by allowing for the storage of these records in a centralized, audit-ready environment. These platforms are often designed with compliance in mind, offering version control, electronic signatures, automated workflow approvals, audit trails and secure access management. An ERP system tailored for life sciences integrates documentation directly into your daily operations, offering several crucial advantages:

Centralized Document Repository: ERP systems store compliance documents in a centralized database accessible by authorized users. This ensures everyone works from the most current versions, eliminating risks associated with outdated or incorrect documentation.

Integration of Documentation Into Workflows: Rather than handling compliance documents in isolation, life sciences ERP systems allow you to embed document creation, review and approval, like for SDSs or MMRs, directly into larger business processes such as new item setup, production planning or vendor onboarding. As a result, compliance tasks happen in context, on time and in alignment with your operational milestones.

Enhanced Traceability and Audit Trails: Specialized ERP systems offer robust tracking capabilities for ingredients, batches and finished goods. They can generate detailed audit trails that document every action, from material receipt through final product release, significantly simplifying audits and regulatory inspections.

Real-Time Visibility and Reporting: ERP solutions provide real-time visibility into compliance status, allowing rapid identification and correction of documentation issues. Reporting and analytics features help your business monitor performance, manage risk and continuously improve documentation practices.

By embedding compliance documentation management within your operational workflows, a life sciences ERP solution reduces risks, improves efficiency and facilitates regulatory compliance.

Take Control of Your Compliance Documentation With Aptean

Document management in life sciences isn’t optional: it’s mission-critical. From compliance to quality to reputation, everything depends on how well you control your documents. By leveraging a life sciences ERP with compliance features, you can simplify operations, reduce risk and support sustainable growth.

That’s where Aptean makes a difference. Our ERP solution for life sciences is built with compliance at its core, helping you manage critical documents like SDSs, CoAs, MMRs and BPRs with confidence. Backed by expert-led support, purpose-built functionality and a cloud-ready platform, we empower your team to stay audit-ready, reduce risk and scale without compromising on quality.

Want to learn more? Explore how Aptean can help you get a handle on managing your compliance documents with a demo of this functionality, or get in touch with our expert team for more information

Ready to Start Transforming Your Business?

We’ve got the specialized ERP solutions you need to conquer your industry challenges.