Your Full Warehouse Management System Guide

Your Full Warehouse Management System Guide

Your Full Warehouse Management System Guide

17 Sept 2025

Aptean Staff Writer

Aptean Staff Writer The Quick Read: Core Points Only

If you just want the highlights, here are the big questions about WMS—answered fast:

What is a WMS: A warehouse management system (WMS) optimizes warehouse tasks from receiving and inventory management to picking and shipping.

WMS’s role in the supply chain: A WMS connects upstream suppliers through your ERP system and downstream shipping integrating with your transportation solutions.

Benefits of cloud-based WMS: Learn how cloud solutions offer flexibility, scalability, automatic updates, mobile access and AI-readiness.

What features matter most: Identify must-have tools like real-time tracking, barcode scanning, flexible picking methods, seamless integrations and reporting.

What are the key benefits: Greater accuracy, faster fulfillment, better labor use and smarter space management.

Warehousing is often seen as a behind-the-scenes aspect of business, but it truly serves as the heart of your operation and deserves some of the limelight. When challenges arise in your warehouse, the impact can be felt throughout your entire company, leading to order delays, misplaced inventory and unhappy customers.

That's why having a solid warehouse management system (WMS) is essential. Without a WMS, you risk encountering inefficiencies and inaccuracies that could seriously affect your bottom line and customer satisfaction.

But if you’re currently using manual methods, basic tools or haven’t upgraded your system in a long time, the thought of implementing a purpose-built warehouse system can be daunting. The good news is that understanding what a WMS can do—and how it directly benefits your business—is simpler than you might think.

In this guide, we'll explore everything you need to know about WMS: its functionality, its benefits, how it integrates into your supply chain and the key features to prioritize when making your selection. We promise clear, actionable insights without any fluff—just practical advice to help you understand and implement the best solutions for your business.

What Is a Warehouse Management System?

A warehouse management system is designed to optimize and control warehouse operations. Its significance lies in ensuring that every step—from receiving products to shipping them—is carried out accurately and efficiently.

WMS software meticulously tracks your inventory, enhances your picking and packing processes and empowers your team to perform their best. Whether you're managing one facility or several, the right WMS can turn chaos into a smoothly running operation. For those with multiple locations, it provides centralized management, real-time insights and smart resource allocation that lift the burden off your shoulders. Core functions of a WMS include:

Receiving and putting away goods

Real-time inventory tracking

Order picking, packing and shipping

Stock adjustments, transfers and cycle counting

Reporting on inventory, order status and warehouse performance

Modern WMS platforms are highly adaptable and can handle various warehouse configurations, including palletized goods and item-level tracking. Many systems are also integrated with enterprise resource planning (ERP) software, enabling smooth data flow across business operations.

Why Do You Need a WMS?

Your warehouse is the hub where supply meets demand. Without effective management, it becomes a bottleneck. A WMS addresses common operational challenges by:

Monitoring inventory in real time

Improving warehouse layout and storage efficiency

Eliminating manual data entry and reducing human error

Accelerating order fulfillment

Enabling scalability as your business grows

Whether you operate a small backroom storage area or a high-volume distribution center, a WMS brings consistency, control and efficiency to your warehouse operations.

What Key Warehouse Processes Does a WMS Support?

Receiving Operations

Receiving is the first touchpoint in your warehouse’s workflow. A WMS makes it faster and more reliable by:

Verifying incoming shipments against purchase orders

Automatically assigning optimal storage locations

Capturing product data (e.g. lot numbers, expiration dates) and updating inventory instantly

This ensures new stock is processed accurately and gets to the right location quickly.

Storage and Inventory Control

Effective inventory control starts with smart storage. A WMS helps by:

Slotting fast-moving items in accessible areas

Keeping track of stock by SKU, lot or serial number

Automating cycle counts and reducing the need for full physical inventories

The result is a highly organized, accurate inventory system that saves time and reduces errors.

Picking and Packing

A strong fulfillment process is key to customer satisfaction. A WMS enhances it through:

Intelligent pick list creation based on order priority

Support for multiple picking strategies (wave, zone, cluster, batch)

Accurate packing and labeling to ensure the right order goes to the right customer

Efficient picking and packing mean faster shipping and fewer returns.

Returns and Reverse Logistics

Returns are an unavoidable part of doing business. A WMS simplifies returns by:

Streamlining return check-ins and inspections

Deciding whether items should be restocked, refurbished or discarded

Maintaining traceability and inventory accuracy through every step

With better visibility and defined processes, your team can manage reverse logistics with confidence.

Where Does a WMS Fit in the Supply Chain?

So, where exactly does a WMS fit in the big picture of your supply chain? It's a strategic operational bridge between upstream and downstream processes—right in the middle of your logistics ecosystem. While your ERP might handle purchasing and planning and your transportation management system (TMS) takes care of shipping and delivery, a WMS sits squarely in the warehouse, orchestrating everything that happens between inbound receipt and outbound fulfillment.

That means WMS functionality kicks in after goods arrive from suppliers, directing where they’re stored, how they’re picked, packed and shipped and how inventory levels are maintained in the meantime. It plays a pivotal role in making sure the right products are in the right place at the right time. And when it’s integrated with your other systems—ERP, TMS, ecommerce platforms—it enables:

More intelligent replenishment based on actual stock and order velocity

Higher order accuracy and improved on-time, in-full (OTIF) rates

Better warehouse labor utilization

Real-time inventory visibility across the whole supply chain

In short, a WMS connects the dots between supply and demand, turning your warehouse into a key performance driver rather than just a storage facility.

Which Industries Use a Warehouse Management System?

WMS software is a proven solution, widely used across nearly every industry that handles physical goods. Its effectiveness isn’t limited to large corporations—small and midsize businesses benefit too.

Industries that rely on WMS include:

Manufacturing – Track raw materials and finished goods throughout production

Wholesale and Distribution – Manage bulk inventory and fast B2B cycles

Retail and E-commerce – Handle high-SKU volumes, multichannel orders and returns

Food and Beverage – Ensure traceability, freshness and regulatory compliance

Third-Party Logistics (3PL) – Deliver customized solutions for multiple clients

Transportation and Logistics – Coordinate warehousing with shipping and freight

WMS platforms, from pharmaceuticals to apparel, can be tailored to fit industry-specific workflows and compliance needs, showcasing their adaptability across diverse sectors.

Types of Warehouse Management Systems

When it comes to warehouse management systems, businesses have several options—and the right choice depends on your size, industry, IT resources and long-term goals. To help you evaluate, here are the main types of WMS and how they differ:

Standalone WMS: A specialized tool focused solely on warehouse operations. Suitable for businesses with specific warehousing needs that don't require full ERP integration.

Integrated WMS: Embedded within or connected to a broader ERP or supply chain suite. Offers seamless data sharing across departments.

Cloud-Based WMS: Hosted remotely and accessible through browsers and mobile apps. Ideal for businesses seeking scalability and lower IT overhead. We’ll dive into the importance of cloud WMS in the next section.

On-Premise WMS: Installed on local servers and managed internally. Not the ideal choice for most businesses today, but organizations with specific control or security needs may still require it.

Beyond these core categories, it’s also important to weigh factors like industry-specific functionality and the vendor’s track record, as both can make a significant difference in how well the system supports your unique operations and long-term goals.

Why Choose a Cloud-Based WMS?

A cloud-based WMS delivers the same core functionalities as an on-premise system, but with added flexibility, faster implementation and lower long-term costs. Let’s break down what makes it such a wise choice for growing organizations.

Lower upfront investment: With a cloud-based WMS, there’s no need to purchase expensive servers or infrastructure. That means you can skip the heavy capital expenditure and simply pay for what you need—whether that’s monthly or annually.

Rapid deployment: Setting up a cloud WMS is significantly faster than installing and configuring an on-premise system. There’s no complicated hardware to install or software to update manually. Most cloud WMS platforms are ready to go within weeks, so you can start optimizing warehouse operations almost immediately.

Scalability: Whether you’re onboarding new employees, opening additional warehouses or expanding into new markets, a cloud-based system can easily grow with your business. You can add users, features and locations with just a few clicks—no downtime, no disruption.

Automatic updates: You’ll never have to worry about falling behind on software versions or security patches. Cloud WMS vendors handle updates automatically. So you can ensure that you’re always running the latest version with the newest features, compliance improvements and performance enhancements.

Mobile access: One of the biggest perks of a cloud-based platform is the ability to access your WMS from anywhere. Warehouse managers can log in from a mobile device, tablet or laptop—on-site or remotely—to get real-time visibility into operations, inventory and order status.

AI-readiness: Cloud infrastructure makes it easier to adopt emerging technologies such as artificial intelligence (AI), machine learning and advanced analytics. This means you can quickly take advantage of next-generation functionality like predictive demand forecasting, intelligent slotting, or automated labor optimization without the need for heavy IT investments.

Cloud-based WMS solutions are also built with integration in mind. They play nicely with e-commerce platforms, TMS, ERP software and other digital tools, making them ideal for modern, interconnected supply chains. If your business thrives on agility and growth, the cloud is your best bet.

What Are the Key Features to Look for in a WMS?

The goal isn’t just to find a WMS with the basics, but one that can streamline your processes and scale with your business—right out of the box. Here are the essential WMS features to look for to actively improve your workflows without constant workarounds, add-ons or costly customizations:

Real-time inventory tracking and visibility: A WMS gives you live updates on stock levels, item locations and movements—so you never have to wonder where anything is. This reduces the risk of stockouts, overstocking and inventory write-offs.

Barcode and RFID scanning: These tools automate data capture during receiving, picking and shipping, drastically improving speed and accuracy. Plus, they reduce manual errors, streamline audits and improve traceability.

Mobile device support for receiving, picking and cycle counting: Modern WMS platforms support handheld devices and tablets, allowing your team to manage tasks from anywhere in the warehouse—no more walking back to a desktop terminal.

Flexible picking methods (wave, batch, zone, etc.): Every operation is different, so your WMS should support multiple picking strategies to match your order profiles and volume. Whether you need wave picking for peak periods or zone picking for large facilities, flexibility boosts fulfillment speed.

Seamless integration with ERP, TMS and ecommerce platforms: Your WMS shouldn’t live in a silo. The best systems connect with ERP software for financials, TMS for shipping and ecommerce platforms to sync orders and inventory automatically.

User access control and role-based permissions: Security matters. Role-based access ensures that team members only see the data and tools they need, reducing risk while simplifying the interface for users.

Automated replenishment and low-stock alerts: Stay ahead of demand by setting up triggers that alert you—or even reorder—when inventory dips below a threshold. This keeps stock flowing without manual oversight.

Reporting and dashboards for performance monitoring: A good WMS gives you more than data—it delivers insight. Use real-time dashboards and historical reports to spot bottlenecks, track key performance indicators (KPIs) and make smarter decisions.

What Are the Benefits of Implementing a WMS?

A well-implemented warehouse management system can become the backbone of operational efficiency across your supply chain. Whether you're running a manufacturing facility, distribution center or ecommerce warehouse, the advantages of a WMS go far beyond basic inventory tracking.

Increased inventory accuracy: One of the most immediate benefits of a WMS is a dramatic improvement in inventory accuracy. By automating item tracking and syncing real-time data, a WMS minimizes human error and eliminates the need for manual stock counts. This precision reduces stock discrepancies, cuts down on costly write-offs and enables smarter purchasing decisions that align with actual demand, keeping your warehouse lean and efficient.

Faster order fulfillment: Speed is everything when it comes to fulfilling customer expectations. A WMS helps streamline picking, packing and shipping operations by automating pick list generation and optimizing pick paths. Whether you're using batch, zone or wave picking, orders move faster with fewer errors—meaning happier customers, fewer returns and a competitive edge in fast-moving markets.

Higher labor productivity: With a WMS guiding daily tasks, your team spends less time figuring out what to do and more time getting it done. From assigning pick routes to directing put-away tasks, the system ensures every movement counts. This intelligent task management reduces idle time, increases throughput and supports labor planning, ultimately enabling you to get more out of the same workforce without burnout.

Better space utilization: Every square foot of your warehouse costs money—so why let it go to waste? A WMS helps you make the most of your storage space by intelligently slotting items based on demand frequency, size or temperature requirements. It also helps prevent stock overflows and disorganized aisles by maintaining optimal inventory levels. The result is a cleaner, safer and more productive warehouse environment.

Real-time visibility: A WMS provides real-time, centralized visibility into your warehouse operations, from current stock levels to order statuses and performance metrics. This transparency helps warehouse managers respond quickly to issues, forecast demand more accurately and communicate confidently with other departments or customers. It also lays the groundwork for data-driven decision-making across your entire supply chain.

Scalability and cost reduction: When your operations run smoothly, costs naturally fall. With fewer picking errors, faster turnaround and better resource management, a WMS reduces waste across labor, inventory and time. And as your business grows, the system scales with you—allowing you to handle higher order volumes, add new locations or diversify your product range without missing a beat.

Implementing a WMS: What To Expect

Launching a WMS is a major project—but the right approach ensures success. Here are the typical phases:

Requirements Gathering: Map out current workflows and define future goals

Vendor Evaluation: Compare solutions based on functionality, scalability and support

System Configuration: Customize the system to match your warehouse layout and processes

Integration: Connect the WMS with ERP, ecommerce or other software

Training: Prepare warehouse teams for go-live with role-specific instruction

Go-Live and Support: Monitor early usage, troubleshoot issues and fine-tune settings

Choosing a vendor with deep implementation expertise can dramatically shorten your timeline and improve outcomes.

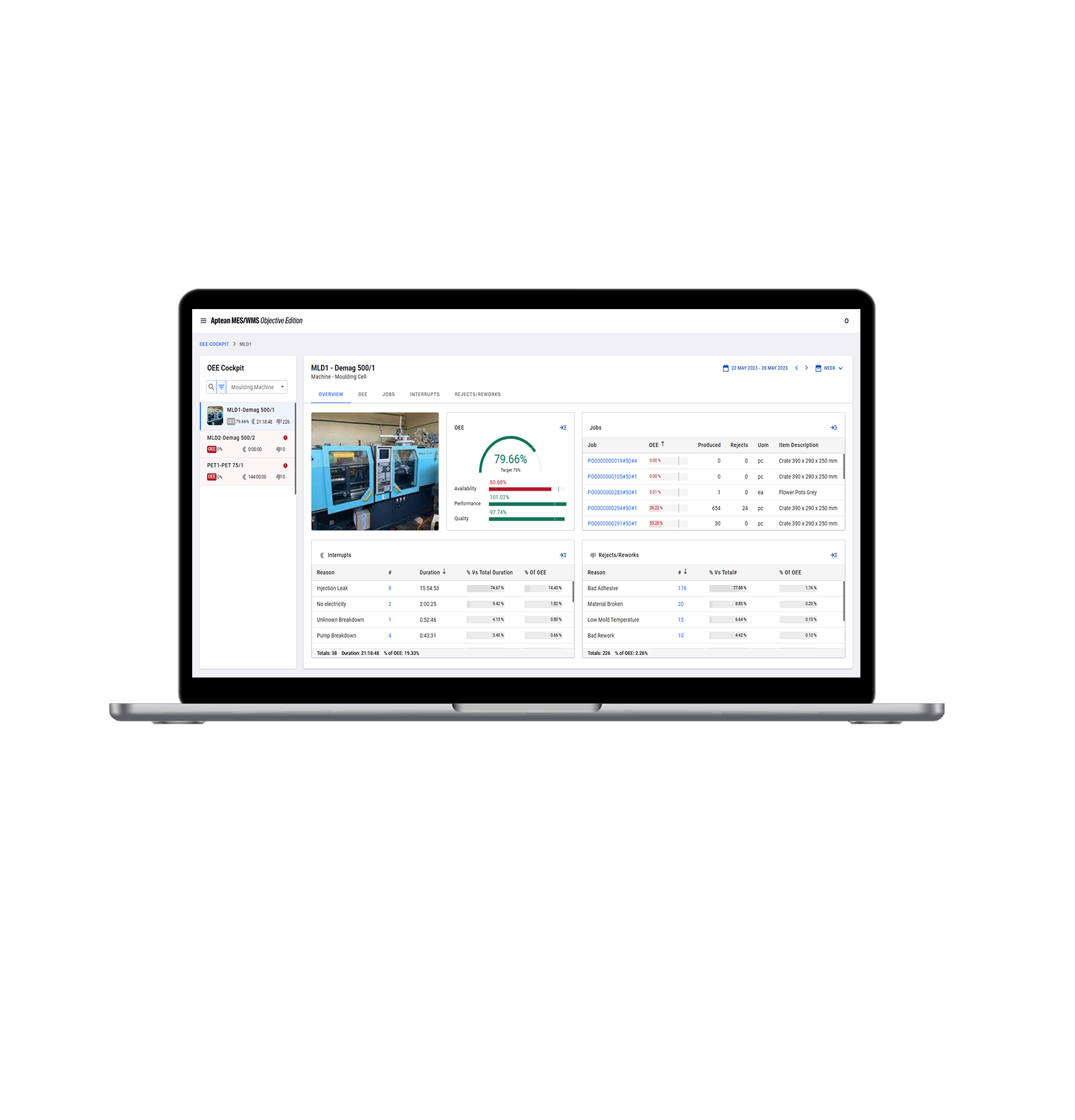

Powering Smarter Warehousing With Aptean

At Aptean, we know that your warehousing challenges can’t be solved with yesterday’s tools. You need a WMS that stays ahead. That’s where our advanced warehouse management systems come in: whether it’s ProWMS for large or complex business setups or Indigo WMS for midsize and smaller organizations, we’ve got you covered.

With real-time visibility and intuitive dashboards, you’ll always know where your inventory stands—no guesswork, no delays. Our smart picking and packing workflows help you fulfill orders faster and with greater accuracy, which means fewer complaints, happier customers and better margins. This level of control and confidence in your operations is what Aptean WMS is all about.

Our cloud-native design means you can say goodbye to server headaches, lagging updates and integration barriers. Whether you’re syncing with an ERP, plugging into your transportation software or selling across multiple ecommerce platforms, our WMS seamlessly integrates with your existing tech stack.

But the real difference? We don’t just hand over the keys and walk away. Aptean’s by-your-side approach means our experienced team is with you from kickoff to go-live and beyond—offering expert guidance, process improvement advice and ongoing support. This level of support ensures you feel secure and supported in your investment, knowing you're getting the most from your warehouse management system.

If you’re ready to reduce overhead, deliver faster and take control of your warehouse operations—without sacrificing flexibility or growth potential—Aptean has your back. Our purpose-built WMS software is designed for real-world complexity, across industries like food and beverage, fashion, logistics and discrete manufacturing.

Let’s build a smarter warehouse together. Contact us or request a demo to get started.

Prêt à transformer votre entreprise ?

Nous avons les solutions WMS spécialisées dont vous avez besoin pour relever les défis de votre secteur.