Fast Decision-Makers Win in the Perishable Goods Supply Chain

Fast Decision-Makers Win in the Perishable Goods Supply Chain

Fast Decision-Makers Win in the Perishable Goods Supply Chain

30 Avr 2025

Sheldon Peacock | Director, Product Management

Sheldon Peacock | Director, Product Management

The luxury of time doesn't exist in the fresh food industry. With produce deteriorating by the hour, delays directly translate to financial losses.

When premium retailers demand perfect goods, perishable food supply chain executives have minutes to redirect inventory, preserve margins and fulfill commitments.

The leaders who master these high-pressure moments protect profits and maintain customer relationships to drive long-term revenue security.

Every Minute Costs You Money

Each day, millions of dollars in fresh produce deteriorates while delayed by supply chain issues.

Around one-third of all food produced globally is lost or wasted; that’s 1.6 billion tons of primary product equivalents.

For fresh produce, wastage presents not just an environmental catastrophe but an enormous financial drain that compounds across every stage of the perishable goods supply chain.

Just look at inventory management. Over-purchasing leads to waste and write-offs, while under-purchasing creates stockouts and lost sales opportunities. Without data-driven decisions, fresh produce businesses remain trapped in a costly guessing game.

The solution? Real-time inventory systems that enable rapid decisions and minimize waste. Companies like yours aren't just using technology to reduce spoilage; they're protecting profits where their competitors accept losses.

Tradition vs. Technology: Why Data Wins

The industry has long operated on a relationship-based approach to fresh produce supply chain management. Typically, all produce is received, regardless of quantity or quality. There's no point in rejecting perishable produce arriving at your warehouse, as sending it back would consume all remaining shelf life, rendering it worthless.

This dynamic has created a distinctive culture where trading partners work together to ensure produce gets sold. And this approach has served the industry for generations.

However, the traditional model falters in today's complex global supply chain. Climate volatility, rising consumer expectations and razor-thin margins demand precision that reactive management cannot provide.

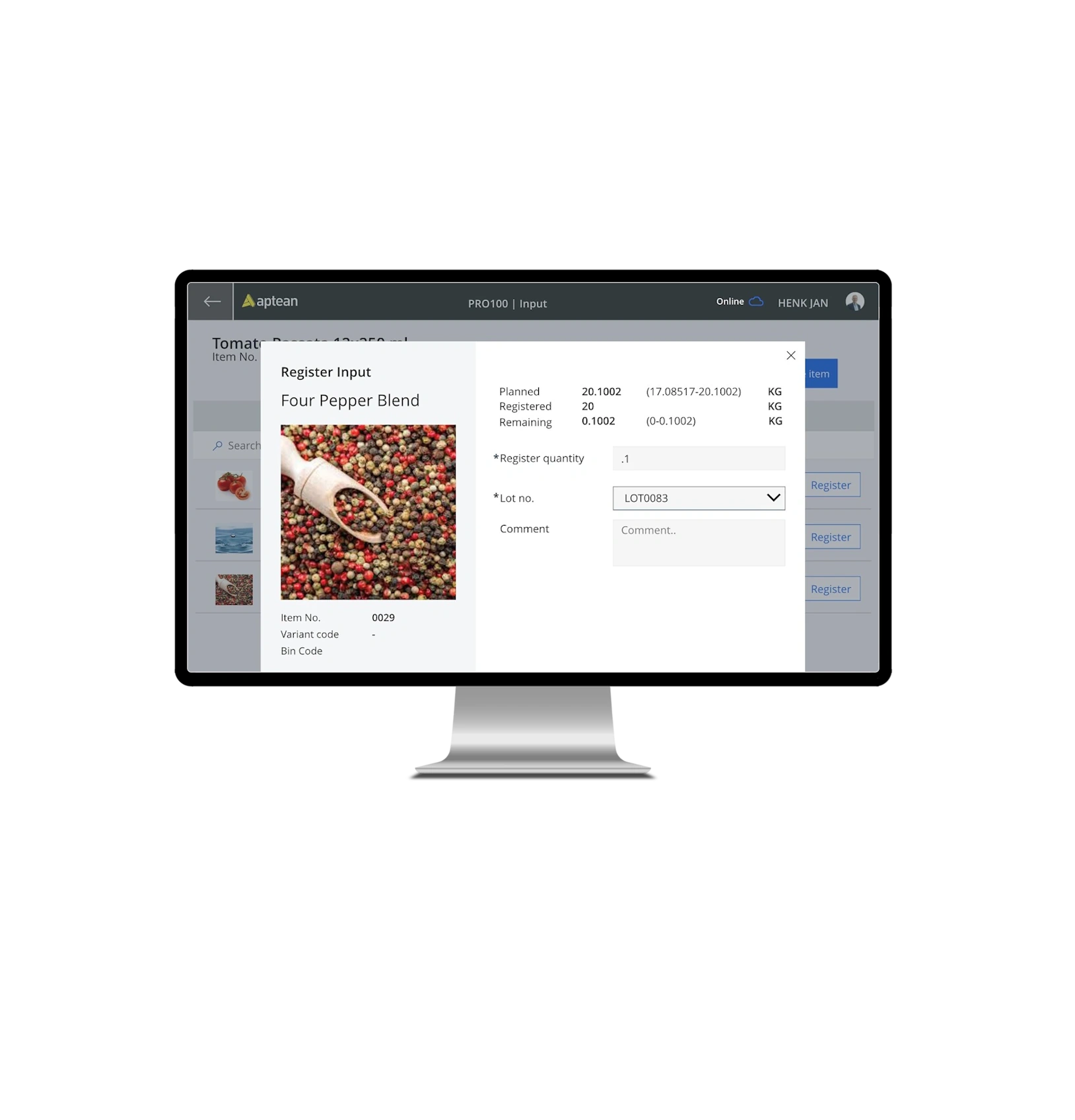

Your fresh produce operations require granular, real-time visibility into inventory conditions across the entire supply chain. This kind of traceability and transparency is made easy with purpose-built fresh produce software that tracks not just quantity, but quality attributes that determine value, shelf life and optimal market destination.

Tracking Quality Alongside Quantity

In your industry, inventory accuracy extends far beyond simple counts. It encompasses quality, color, size, grade and other critical attributes that determine market value. These multi-dimensional elements must be tracked throughout the entire perishable goods supply chain—from intake through processing, shipping and customer delivery. Perishability means quality can degrade at any point if products aren’t properly monitored and managed.

Technology enables the rapid decision-making needed when dealing with perishable products so that your business can route items to appropriate channels and maximize value. Without this capability, your fresh produce company will remain trapped in reactive cycles.

When Disaster Strikes, Quick Decisions Pay Off

When a heatwave swept through California's Central Valley in 2024, temperatures exceeded 100 degrees Fahrenheit. Farmers faced scorched fields and water rationing, resulting in significant yield reductions for key crops.

This climate disruption created the exact scenario that challenges fresh produce supply chains. Expected premium-grade inventory suddenly became medium-grade, so providers had to quickly determine how to market the produce while still fulfilling high-end retail commitments.

Companies with advanced supply chain management systems redirected affected inventory within hours to appropriate secondary channels. Simultaneously, they secured alternative premium-grade products from unaffected growing regions to maintain contracted agreements.

In contrast, their competitors took days to adjust, absorbing losses that directly impacted quarterly earnings and damaged key retail relationships.

Putting Profitability Back Into Perishable Goods

Growth in this industry isn't always about moving more volume. It's about extracting maximum value from every peach, tomato and lettuce head before time diminishes their worth.

Your fresh produce company can overhaul how you manage perishability and boost resilience by implementing integrated systems that empower you to:

Compress decision cycles from hours to minutes. Real-time quality assessment systems use artificial intelligence (AI) to evaluate entire shipments in seconds, eliminating manual sampling limitations.

Transform market volatility into opportunity. Predictive analytics forecast quality distribution from specific vendors, allowing proactive channel allocation before products arrive.

Increase financial visibility. The most sophisticated operations now produce profit analyses by load, shipping container or even field of origin.

Staying ahead of variances can help your company adjust procurement patterns to prevent food waste while ensuring sufficient yield for customers.

Stop Wasting Money on Spoiled Produce

Every hour that fresh produce sits in your warehouse represents thousands in value deteriorating in real time.

The most sophisticated organizations have moved beyond reactive management to predictive supply chain optimization. They can anticipate quality variations and strategically position inventory.

Climate disruption, market volatility and fluctuating retailer demands aren't temporary challenges; they're the new normal. To thrive in this unpredictable environment, your business needs to act fast.

Turn to Aptean, a trusted and proven provider of AI-enhanced solutions that equip fresh produce companies with the capabilities they need to handle the challenge of perishability.

From advanced supply chain management features to uncompromising quality control tools, our solutions, such as Aptean Fresh Produce ERP, deliver a wealth of cutting-edge industry-specific functionalities.

For more insights on this topic, download our executive briefing: Transforming the Fresh Produce Supply Chain. In this free resource, industry experts discuss how fresh produce leaders are turning split-second decisions into sustainable competitive advantages.

And if you’ve got additional questions, feel free to contact us. You can also request a personalized demo to see our solutions in action.

Contactez-nous dès aujourd'hui pour parler à un expert de votre secteur

Pour développer votre entreprise, vous avez besoin d'un ERP alimentaire conçu spécifiquement pour les défis de votre secteur. Nous sommes prêts à vous aider—contactez-nous dès aujourd'hui et nous vous aiderons à trouver la solution adaptée.