Featured in this post

The Top 6 Challenges in Food Warehouse Management and How Purpose-Built Software Solves Them

The Top 6 Challenges in Food Warehouse Management and How Purpose-Built Software Solves Them

30 Mar 2023

John McCurdy | Senior Content Writer, Marketing

John McCurdy | Senior Content Writer, Marketing

When you imagine the warehouse of a food and beverage business, what comes to mind? Is it endless rows of bins and shelves holding all manner of ingredients and finished products? Perhaps you see a storm of human activity as employees—some driving forklifts, others wheeling pallets or consulting clipboards—hurry about to conduct their tasks?

Or, do you instead think of how overwhelming it would be to keep such a busy and jam-packed space in order and operating smoothly? If so, know you’re not alone in being a bit intimidated by warehouse management in the food industry. And thankfully, technology that makes the whole matter far less burdensome and prone to complications exists.

You may already be somewhat familiar with the kind of software we’re referring to, namely warehouse management systems (WMS) or—better yet—industry-specific enterprise resource planning (ERP) platforms with integrated WMS functionalities. But to fully understand how powerful these solutions are and the positive impact they can have, you need to go a little deeper.

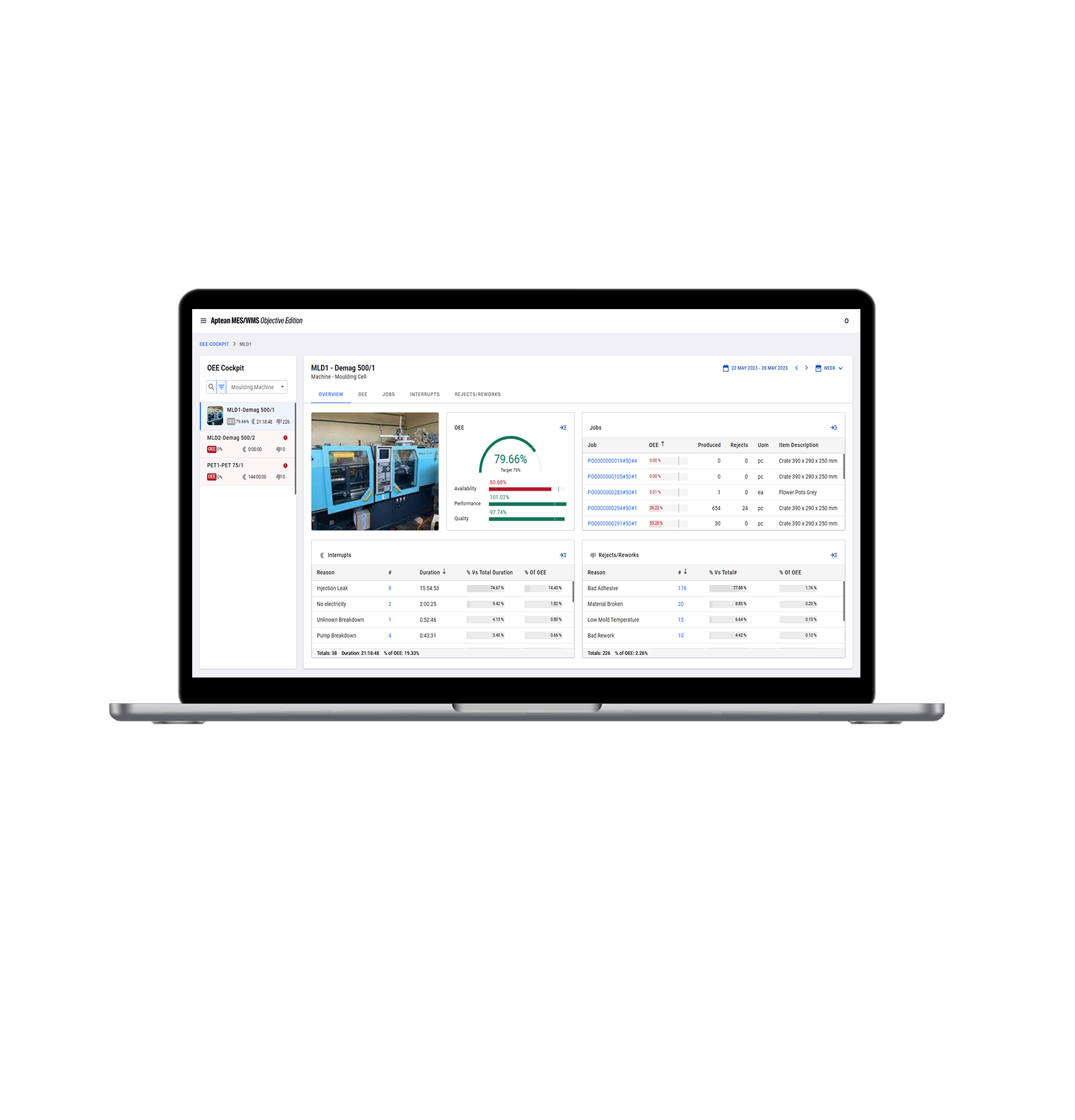

That’s why we’ve curated this collection of the top six challenges in food warehouse management and how purpose-built software solves them. We’ll also highlight how our award-winning food ERP solution, Aptean Food & Beverage ERP, goes beyond the basics and offers advanced features that can help your company excel on this all-important front.

Challenge 1: Maintaining Bidirectional Traceability

Having a complete picture of the movement of your materials from one end of the supply chain to the other is crucial for food safety and recall preparedness, but it’s equally vital for establishing a clear high-level view of where your resources have been, are now and will be heading next. Without that, your warehouse management efforts would be crippled before you even began.

Solution

The lot and sublot management features of ERP systems help you track inventory from its point of origin to receiving and storage and onward to manufacturing and finished product delivery. These tools allow users to define lots deeply with a variety of criteria, including country of origin, production date, variety, certificate numbers and more.

Aptean Food & Beverage ERP also has built-in functionality for using common lot numbering and identification schemes, like license plating and serial shipping container codes (SSCCs). With our solution in place, your team will be equipped to maintain full visibility of the path your goods take and leverage that to make informed decisions on the fly.

Challenge 2: Keeping Inventory Levels Optimal

Procuring the ingredients you need to fulfill orders without ending up with excess is a difficult balance to strike, and that’s without taking into consideration how challenging it can be to predict the appetite of the market. If you can’t tune your inventory to optimal levels for the circumstances you face, you risk losing your investment in materials you can’t use and missing out on chances to generate revenue.

Solution

Production planning features of food ERP software are some of the most important for food and beverage organizations, as these help you to precisely align your supply with customer demand. That helps to ensure that you can take full advantage of the raw ingredients you purchase as well as the sales opportunities that come your way while avoiding the problem of waste that hurts your bottom line.

Our system takes this a step further with robust forecasting functionalities that factor in historical sales data, current supply quantities and seasonality to create reliably accurate predictions of the order volume you can anticipate. That saves your employees time, as they don’t have to export, analyze and summarize the facts and figures locked in spreadsheets, and gives your business a competitive edge.

Challenge 3: Ensuring Product Quality Meets Standards

One bad experience can turn a loyal brand champion into a vocal detractor, and there are few industries in which consumers are so discerning as they are when it comes to food and beverage products. Protecting your company’s reputation and doing all you can to promote customer satisfaction isn’t easy, though—at least not when your staff lack the specialized tools that these tasks require.

Solution

As one of the most indispensable components of an ERP platform, quality control features provide key functionality that facilitate conducting important checks at various stages in the supply chain. In addition, mobile accessibility allows workers to report their findings from the floor and immediately place on hold any item that fails. Combined together, you can feel more assured that standards are met.

Being able to set inspection statuses for lots and individual items is a game-changer for keeping all team members apprised of what quality checks have already been carried out and what the results were; Aptean Food & Beverage ERP comes with functionalities for just that purpose. You’ll also be able to define quality triggers and workflows when an issue is identified to streamline their rectification.

Challenge 4: Minimizing Waste from Spoilage

When your raw materials spoil before they can be used, your business is out the initial investment you made in those goods without any chance to recoup it, dragging down your profitability. What’s more, food waste is a major contributor to climate change, so these unfortunate instances are also setbacks in your organization’s commitment to sustainability.

Solution

Accounting for the expiration dates of every product in your warehouse would be a complicated task, to say the least, and that’s why it’s a matter best trusted to technology that’s designed for that very specific purpose. The expiration management tools of an industry-specific food ERP solution can help you track the expiration timeframes for all of your items and even deploy alerts when spoilage is imminent.

It’s also worth pointing out how the aforementioned production planning and forecasting features help on this front. When your procurement levels are tuned precisely with your production plans, and those in turn are aligned with your expected sales, you’re far less likely to end up with ingredients that go bad before they can be consumed.

Challenge 5: Improving Efficiency and Accuracy

It almost goes without saying that boosting efficiency and accuracy are crucial objectives for food and beverage businesses, as any company would be incentivized to be more productive and encounter fewer operational errors. However, far too many organizations still rely on paper-based, manual record-keeping methods for warehouse activities, which are both time-intensive and prone to mistakes.

Solution

The fact that ERP systems are inherently digital in nature and can serve as the “single source of truth” organization-wide is significant on its own when it comes to speeding up processes and ensuring accuracy in warehouse management. Aptean Food & Beverage ERP goes further with advanced warehousing features that are both user-friendly and tailored to the unique needs of the industry.

That said, mobile capabilities—including integration with handheld barcode scanners and other mobile devices—take our solution for food warehouse management to the next level in this regard. Workers on the warehouse floor can easily log important data in real time with a single pull of a trigger or push of a button, making their duties less time-consuming and less subject to problems resulting from bad memory or sloppy handwriting.

Challenge 6: Managing Allergens Effectively

As much as 10% of the global population has a food allergy, and the negative health impacts of coming into contact with a problematic substance range from minor annoyances to life-threatening circumstances. As a food and beverage company, you must do all you can to protect end-consumers from adverse outcomes, but that’s challenging when your warehouse is packed with a wide variety of goods.

Solution

Effectively segregating allergens from other ingredients and products is much easier when you can easily identify the lots and individual items with potentially problematic ingredients. That’s best done with the versatile product specifications features of food ERP software, which allow you to clearly flag in the system all goods that carry such food safety concerns for all stakeholders to see.

The advanced attributes and comments functionality of Aptean Food & Beverage ERP let you get even more granular in providing the details on what products might need allergen disclosures (in the case of shared machinery or surfaces) or declarations (in the case of inclusion of the ingredient). That will help you manage allergens with fewer errors and less liability.

Aptean: Leading Solutions from a Trusted Provider

Hopefully now it’s clear that with the right technology on your side, food warehouse management doesn’t have to be as nightmarish as it might seem on first blush. In fact, with advanced food ERP software—like Aptean Food & Beverage ERP—you can maintain traceability and optimal inventory levels while also streamlining your processes and mitigating quality, compliance and allergen concerns.

Our solution is as well-suited to the realities food and beverage businesses face thanks to our team’s collective decades of industry expertise. We really know the ins and outs of the market through first-hand experience, and we’ve got the in-depth understanding of modern best practices to share and thereby improve your company’s results.

An added benefit of choosing Aptean for your ERP needs is our flexible cloud deployments on the Software as a Service (SaaS) model. This setup gives you greater scalability and enhanced data protection, plus tougher cybersecurity and wider accessibility, all while avoiding the need to purchase additional hardware to run the system.

Finally, consider that our unique industry-specific technology is built on the Microsoft Dynamics 365 Business Central platform, which lends it a user-friendly and intuitive interface. And it comes backed by a provider that ranked 30th overall on The Software Report’s Power 500 Software Companies of 2023, placing Aptean in the top 10% of companies on the list.

So, ready to learn more about Aptean Food & Beverage ERP and how it can provide the tools you need to excel in food warehouse management? Contact us today or request a personalized demo.

Ready to Start Transforming Your Business?

We’ve got the specialized WMS solutions you need to conquer your industry challenges.