What Is OEE – And Why Does Your Manufacturing Strategy Need It?

What Is OEE – And Why Does Your Manufacturing Strategy Need It?

What Is OEE – And Why Does Your Manufacturing Strategy Need It?

14 Apr 2021

Aptean Staff Writer

Aptean Staff Writer

They say that time is money—that’s certainly true in manufacturing. To maximize output capabilities, you need machinery that you can rely on. Yet all too often, avoidable problems take production lines down.

If this sounds familiar, what can you do about it? The answer is to put more emphasis on overall equipment effectiveness (OEE).

What Is OEE?

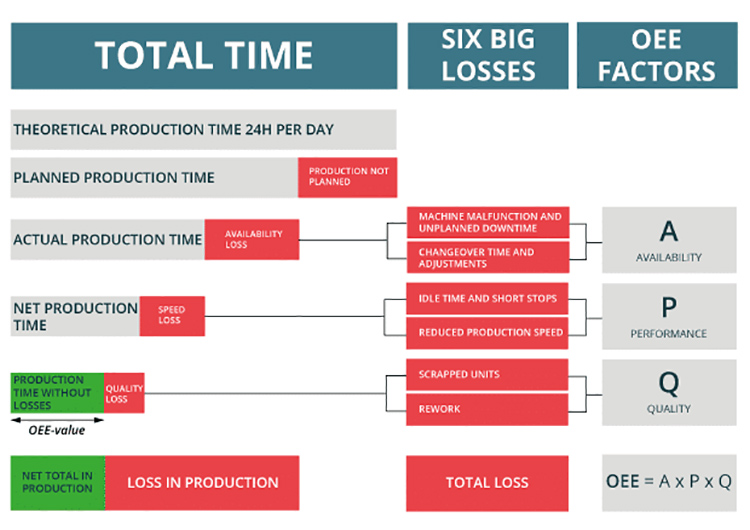

OEE is a measurement that gives manufacturers full insight into their actual productive time against their available planned production time. It takes into account the 6 biggest losses of manufacturing, and it’s an incredibly valuable KPI for your business.

Why Does OEE Matter?

There are several reasons why focusing on OEE will enhance your manufacturing operation.

Firstly, it’s a key metric for improving profit. Mapping actual data against your schedule will enable you to benchmark how effective your equipment is right now, identify any repeat issues, and put strategies in place to optimize your manufacturing processes.

Your goal is to find and eliminate all the losses that arise in production. And being able to understand data and utilize OEE effectively enables you to see where those losses are, and what can be optimized.

Secondly, it’s a great motivator. Tracking OEE gives both management and floor employees targets to aim for, and a reason to celebrate when the improvements you make have a tangible impact on productivity. People efficiency is key.

Thirdly, it’s meaningful across the manufacturing sector. OEE is a universal tool for measuring production effectiveness and identifying potential areas for improvement. So when you’ve got a good OEE score, it’s recognizable industry-wide.

How To Calculate OEE

There are three aspects to calculating OEE. These are:

Quality – your good product out versus total product out. In an ideal world, there will be no defective or scrapped items, but a product that can be reworked is less detrimental than one that must be discarded.

Performance – your actual rate versus standard rate. Ensuring your production process happens at the correct speed, to get through as many jobs as possible each week. Any slow performance will impact actual run time.

Availability – your uptime versus your planned available time to produce. By minimizing downtime (planned or unplanned) to make sure the machinery you need is free to run when you need it. A non-producing manufacturing line increases costs without yielding any value.

Each of these three levers is expressed as a percentage, and they need to function effectively in order to maximize your overall equipment effectiveness score:

100% quality means there are no defective products or parts that need reworking in your business,

100% performance means there are zero speed losses during production, and

100% availability means you don’t suffer from any downtime.

To get your OEE score, perform the following calculation:

OEE = Quality x Performance x Availability

You can measure quality, performance and availability in the following way:

Quality: good products manufactured (meeting quality standards) / total products manufactured

Performance: actual speed / theoretical maximum speed

Availability: uptime / planned available time

Availability

x Performance

x Quality

What’s the Best OEE Software for Manufacturers?

Understanding why OEE will increase productivity is one thing—knowing how to make change happen is another. Most manufacturers enhance profitability by investing in production monitoring software, which will identify where a specific loss is happening and support the right response to help your organization fix the issue.

OEE software is far more than a useful tool for keeping things moving; it’s a means for setting and surpassing strategic goals within your organization. To get the greatest ROI, however, you need to find the best-fit solution for your manufacturing business.

Start by looking at what your current situation is, and the needs you know you have. While an OEE solution will help you see and solve problems, most manufacturers go into software investment knowing where their weaknesses and vulnerabilities lie.

Once you’ve clearly defined your key issues, you can start to set strategies and objectives. How should OEE be applied? At what level? What are your expectations across the deployment period and beyond?

You don’t need the answer to these questions to begin the process—your chosen technology provider can help you develop a response. But framing them in your mind will help you to find a partner that does more than offer OEE software; they understand the pressure you’re under, and the changes you need to make that deliver rapid value.

OEE software is already empowering leading manufacturers to run their business better. Our solution has been developed specifically for the manufacturing industry, to optimize production efficiency and maximize equipment uptime.

At Aptean, we realize that while OEE is a critical KPI, it should be the trustworthy foundation on which well-founded business decisions are made.

Book a free demo to see how our OEE software works.

Ready to Start Transforming Your Business?

We’ve got the specialized OEE solutions you need to conquer your industry challenges.