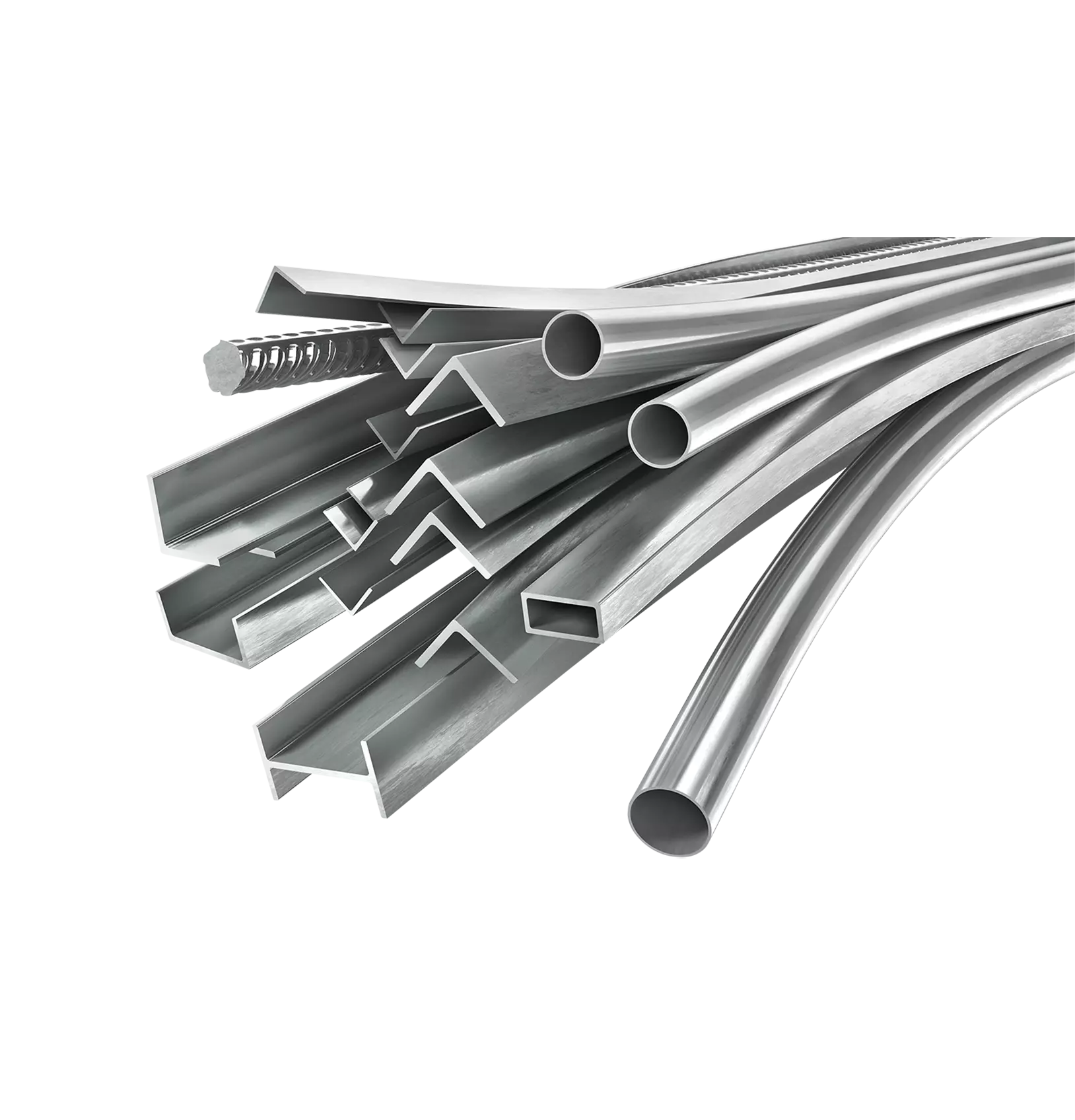

Featured in this post

The Complete Guide to Metal Fabrication ERP Software

The Complete Guide to Metal Fabrication ERP Software

Sep 3, 2021

Aptean Staff Writer

Aptean Staff Writer

Metal fabrication manufacturing is a precision-based industry, where material availability, production schedules and workforce skills must align to meet customer expectations.

This is a huge challenge in itself, but fabricators are facing further obstacles that make running a profitable operation highly complex. Fluctuating demand, increasingly expensive raw materials and skilled labor shortages are all squeezing margins and putting operational performance under a microscope.

While market forces can’t be controlled, technology is opening new doors to help manufacturers run smoother, more efficient and profitable operations. Metal fabrication ERP solutions are empowering manufacturers to streamline processes, plan better and execute more efficiently, to increase speed to market, reduce waste and lower costs.

Ready to unlock these benefits? If so, continue reading our complete guide to metal fabrication ERP software—where you will discover the benefits, and how to find the best-fit solution for your business.

What Is a Metal Fabrication ERP?

In a world of tight margins and precise specifications, attention to detail matters. Enterprise resource planning (ERP) software manages and optimizes day-to-day operations, using digital capabilities and data insight to ensure consistent, high-quality output.

There is a wide selection of generic ERP solutions available on the market, which contain a standard set of features. However, many manufacturers opt for industry-specific ERP software because it’s been designed for the exact needs of metal fabricators. With in-built features to help you to manage capacity, strengthen your supply chain and streamline shop floor operations.

For example, in metal fabrication manufacturing, you may frequently need to switch between units of measurement, to meet customer requirements accurately and limit material waste. If you choose ERP for the metal fabrication industry, this calculation can be carried out automatically, to maximize your use of available resources.

Other key features of industry-specific metals ERP include quoting and estimating capabilities, creating bill of materials (BOM) and production scheduling.

What Are the Benefits of Using Metal Fabrication Software?

We’ve already mentioned that metal fabrication manufacturing is a tight margin, no-room-for-error industry. What makes this sector even more demanding is the fact that metal fabrication is a multi-step process—so there are many areas in which bottlenecks and inefficiencies can occur.

Metal fabrication software adds value by allowing manufacturers to integrate and automate your key processes—from quoting and estimating through to inventory management and production scheduling. And it delivers benefits from end-to-end, such as:

Increasing output by pushing projects from inception and quoting through to the production line, so finished metal products can be in the customer’s hands as quickly as possible (within the same day in some cases). For further insights, read our blog: 5 Ways Fabricated Metal Manufacturers Can Increase Production.

Providing accurate quotes so you can make confident delivery commitments to your customers—particularly if you receive mostly custom orders.

Getting rid of redundant processes and centralizing operations, to improve your speed to market.

Meeting varying customer demands over the way finished components are manufactured and delivered—for example, taking design-to-order requests that may change or evolve during the production process.

Increasing business agility by giving every team and person complete visibility of operational data, in real time.

Improving equipment efficiency – for example, by grouping jobs based on their tooling or nesting requirements rather than the order in which they were received, to reduce changeovers. This ensures that components are consistently created to industry standards while minimizing machinery down-time.

Minimizing supply chain disruption by understanding how material availability and lead times impact your production schedule, to avoid unnecessary delays.

Optimizing inventory, so you’re never held back by material shortages. Optimization can also ensure you aren’t maintaining excess stock, unless it’s a scenario where overstocks are beneficial—for example, volatile or rising steel prices mean it’s better to buy now.

Automating manual tasks so that everyday processes can be completed by technology rather than people, leaving employees free to focus on higher value responsibilities (or liberating you to streamline your workforce).

Enabling complete traceability through supply chain, production and distribution, to support your customers with quality control and regulatory compliance, and in the event of product recalls.

Overall, investing in metals ERP enables manufacturers to cost-effectively improve your turnaround times and meet changing customer needs, without compromising on quality in the process.

What Features Should You Look For in Metals ERP Software?

It’s clear that the benefits of ERP technology are far-reaching. But as we mentioned earlier, many enterprise resource planning solutions are generic—meaning they don’t provide the specific features and functions needed to support the metal fabrication industry.

To make sure your metal fabrication ERP software delivers on promise, look for software that contains these five features as standard. There may be other specialist functions available that will also provide value, but these are a good place to start:

CAD integration. So you can produce accurate quotes and BOMs based on CAD drawings created by you or your customer. CAD integration also means that any changes made during production can be reflected in your material requirements and instructions.

Flexible quoting. To calculate costs based on material needs, labor requirements and other overheads. You can also update those costs from job-to-job as material costs and workforce demands change.

Bill of materials. Many metal fabrication manufacturers will subcontract work out to partners; built-in BOM software allows you to specify the materials, parts and subassemblies for each product to both internal and external stakeholders.

Workload scheduling. So you can plan production based on real-time raw material availability and equipment capacity, adapting your schedule if anything changes during production.

Material resource planning (MRP). Calculate your exact material requirements to reduce waste and manage costs. Then integrate this information with your workforce availability and machine workload capacity planning to run a seamless metal fabrication manufacturing operation.

How To Find the Right Metal Fabrication Software for Your Business

Choosing ERP technology designed for the metal fabrication industry will help to narrow down your shortlist quite quickly, but there are other things to consider when choosing your preferred solution.

As we noted in our recent whitepaper on The 4 Pillars of Future-Ready Manufacturing, think beyond the standard features and capabilities offered by each piece of software you’re considering, to how you are going to use it day-to-day. Now and in the future.

For example, if you are running a multi-site operation, work closely with partners and subcontractors, or have staff members working remotely, on-premise technology will be both expensive and limiting. Instead, look for cloud manufacturing ERP software that your teams can access any time, in any location.

Cloud-based metals ERP can also help to keep costs within budget. There’s no requirement for hardware installation, and your solution can evolve and scale with your business, with minimal complexity.

Another critical thing to consider when buying metal fabrication ERP software is your choice of technology partner. Look for someone who really understands what you’re trying to achieve. Before you commit, ask yourself:

Do they understand what goes into manufacturing metal products? Are they listening to what I want to achieve for my business?

What’s their track record in the fabricated metals industry? Can they share testimonials and case studies from other metal fabrication manufacturers?

What do their onboarding, training and customer support services look like?

Can their ERP software be used out-of-the-box, or does it require complex customizations?

Can it be integrated with other technologies you are using, such as CAD design or accounting software?

Is their metal fabrication ERP software accessible enough for your team to get up to speed quickly, but comprehensive enough to deliver ongoing value?

A software vendor with industry-specific knowledge and experience will not only have an ERP solution that fits your needs; they will be able to help you extract value in the way you deploy and use it. And if the chemistry and culture is right, they’ll partner with you long-term to keep improving your performance.

Why Choose Aptean Metal Fabrication Software?

Aptean manufacturing ERP delivers visibility, control and efficiency to metal fabrication manufacturers. So you can create accurate plans, gain visibility into job costs and profits, and achieve maximum throughput for your organization.

We have a proven track record working with metal fabricators. For example, Aptean ERP has enabled The Metalworking Group (MWG) to increase revenue four-fold and improve on-time, in-full delivery rates by more than 10 percent.

“Aptean Industrial Manufacturing ERP has enabled our growth as a business. We’ve been able to scale up quickly and easily.” - Doug Watts, CEO, Metalworking Group

Our cloud-based ERP software provides tailored functionality straight out of the gate, with no time-consuming customizations or add-ons. To find out more, book your free Aptean metals ERP demo.

Start Transforming Your Operation Today

If you’re ready to take your fabricated metals business to the next level, we’d love to help.