To Maximize Trailer Capacity, Think Time, not Products

To Maximize Trailer Capacity, Think Time, not Products

To Maximize Trailer Capacity, Think Time, not Products

Jul 23, 2020

Mark Massey | Support Manager

Mark Massey | Support Manager

For a delivery fleet that makes many stops per route, route optimization is about meeting all daily delivery requirements while making the least number of trips possible to ensure both fleet efficiency and environmental sustainability. To do that, you want your trailers to be as full as possible.

While trying to maximize trailer capacity, fleet managers often underestimate the importance of time when determining how much to load onto a trailer. That’s where advanced route optimization software is not only useful, it’s essential.

Here’s why.

Trailers can hit maximum capacity in three ways:

Cube out – there is literally no more room on the trailer

Weigh out – the trailer has hit its maximum legal weight

Time out – it’s not possible to add more customer deliveries onto the trailer and still meet ETA commitments or stay within the driver’s hours of service (HOS) limitations

Space and weight are the easy calculations. Routing software can help by automatically tracking both measures as routes are built, using data on box or pallet dimensions and product weight. It’s also possible to monitor cube and weight manually, using spreadsheets and other basic tools.

What’s more difficult in a manual route planning environment is predicting what’s possible in terms of time. A planner may know he can load 40,000 pounds on a trailer, but what he doesn’t know is whether the driver can complete all the deliveries according to the agreed schedule. Therefore, planners are forced to make a subjective judgement.

“Well, 14 deliveries are probably all the driver can handle during the shift, so let’s cap it there,” the planner might say.

If assumptions such as these leave significant room in the trailer, they can be very expensive. Let’s say your vehicles are 10% under-utilized. That could mean three more trucks and three more drivers than needed for a 30-truck fleet – a $700,000 expense based on average tractor-trailer and driver costs.

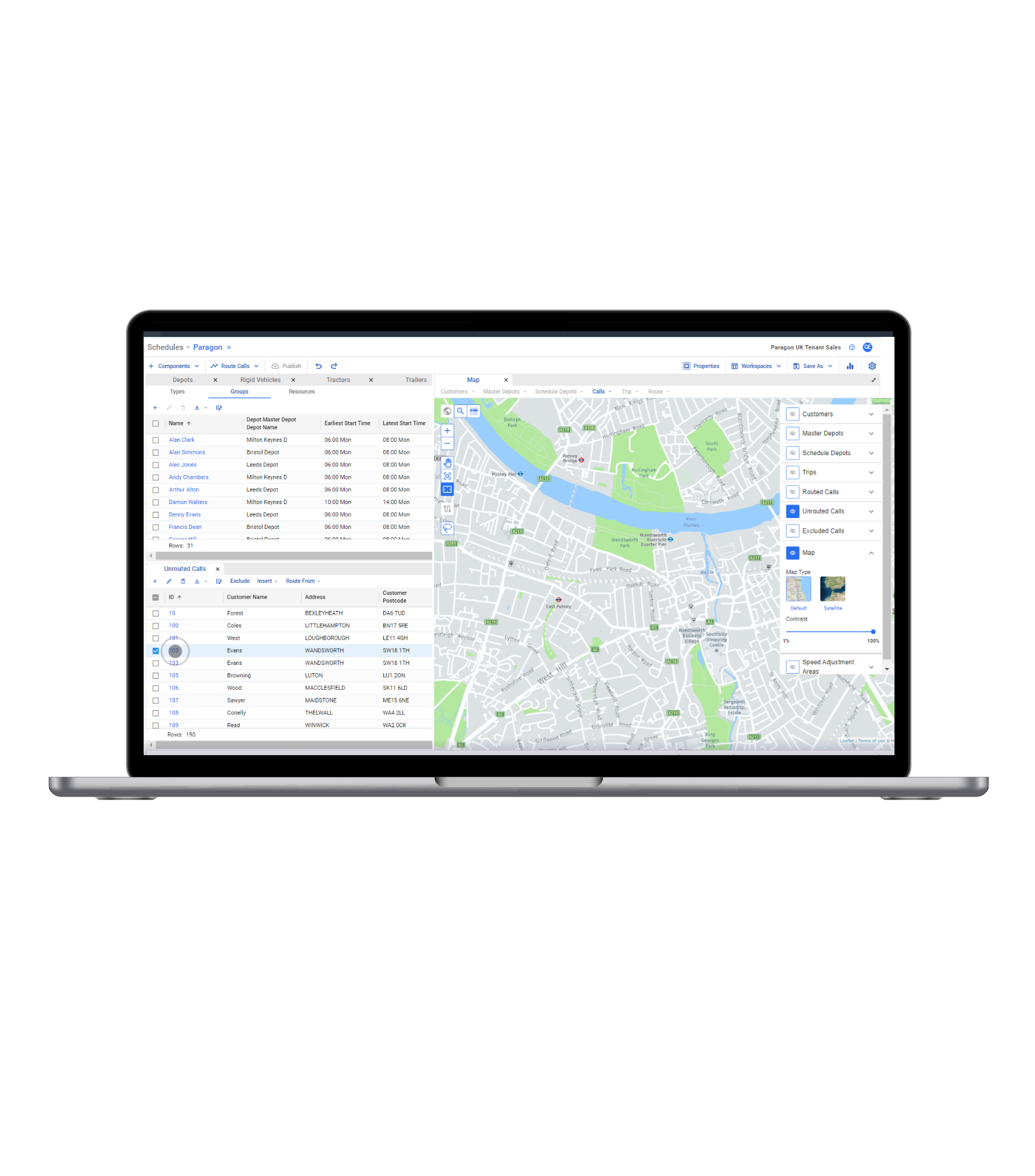

That’s why it is so essential to have software that factors time into the trailer loading process. Advanced applications, like Paragon routing software, look at dozens of factors – including traffic details, unloading and loading times per stop and average road speeds – to let you plan routes and schedules with precise accuracy.

Here’s an illustrative example of the downside of manual route planning that relies on the subjective judgement of planners. Let’s say the plan assumes an average stop time of 20 minutes for each of 18 deliveries, but the actual average stop time – gathered from a simple integration between the telematics and route planning systems – is 15 minutes. With good processes and the right routing software, this actual data gets incorporated into the algorithm and 90 additional minutes of drive time is used to increase the number of deliveries-per-route, creating fuller trucks and a more profitable operation.

When you automate route planning, subjective judgements about what a driver can and can’t do are replaced by data-driven plans that maximize trailer capacity, while ensuring that all routes meet customers’ ETA requirements and keep drivers within their hours of service limits. And the ROI on routing software is fast – typically within 3-12 months.

It’s About Time!

When fleet operators think about maximizing trailer capacity, the focus is typically on monitoring space and weight. But most errors in this area relate more to uncertainty about the time required to execute a set of deliveries along a route. Keeping tabs on space and weight is relatively easy for an experienced transportation professional with a hard-working spreadsheet. But precise calculation of delivery times must consider dozens of variables leading to thousands and thousands of route permutations – well beyond what the human brain can handle.

Thankfully, there’s an app for that. Using route optimization software, fleet operators can maximize trailer capacity on their way to reducing fleet operating costs anywhere between 10–30%. For more information, read Paragon’s Ultimate Guide to Route Optimization, or contact us.

Tried the Product Tour and Ready to Get Into Gear?

Book your full demo with our team today to see how our advanced routing software can help you accelerate performance.