What Is EAM and How Do You Define EAM?

What Is EAM and How Do You Define EAM?

What Is EAM and How Do You Define EAM?

May 13, 2020

Aptean Staff Writer

Aptean Staff Writer

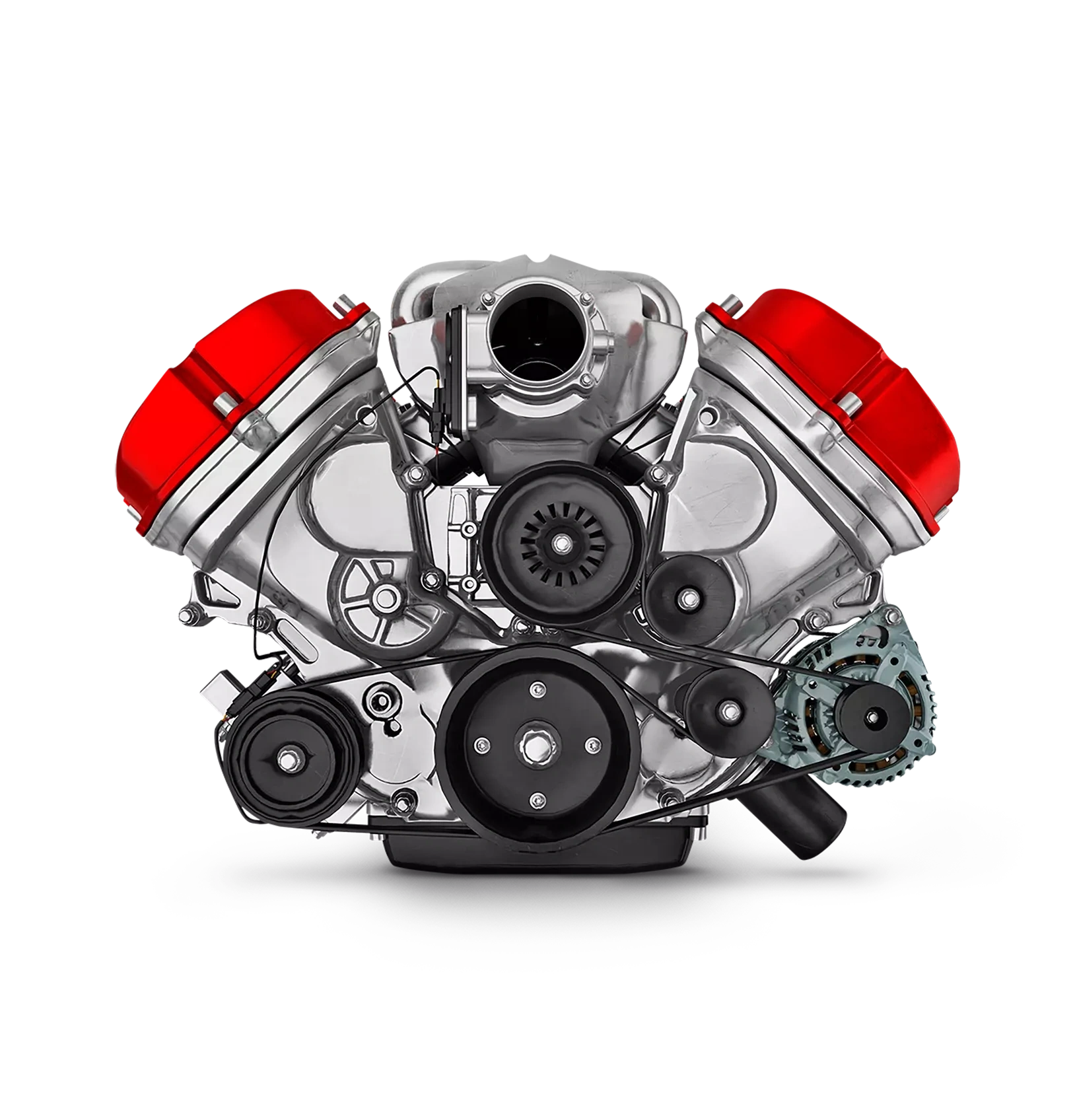

Enterprise Asset Management (EAM) refers to the management of an enterprise’s assets across different facilities, departments, business units and geographical areas throughout each assets' lifecycle. These assets can include plants, buildings, machines, vehicles and infrastructure.

An EAM system is used to plan, control, optimize and execute the needed maintenance activities of the assets with the respective priorities, materials, tools, skills and available information. It includes design, commissioning, operations, maintenance and replacement. The goal of EAM is to optimize an assets life cycle in order to decrease the Total Cost of Ownership (TCO) and at the same time maximizing Overall Asset Productivity (OAP) and Return on Asset (ROA).

Who Needs EAM?

Regardless of what kind of equipment or assets a business owns – they will require maintenance. Monitoring and maintaining business assets is important for every company no matter what size or industry. However, most businesses use EAM as a part of their Enterprise Resource Planning (ERP) systems already. Enterprises that are heavily dependent on complex and expensive physical assets on the other hand find themselves in need of using an independent EAM software to control their assets on a more detailed level. With a stand-alone EAM system, these enterprises are able to gain holistic control over their assets and related maintenance activities.

Why EAM Software Is Key Today

With the progress of Industrial Internet of Things (IIoT) and industry 4.0 a fully-integrated EAM system is vital for asset-heavy enterprises and can minimize risks and optimize business values significantly. Nowadays, vast amounts of data can be used for the analysis of an assets life cycle and predictive maintenance. In practice it can look like this:

Data from machine-connected sensors are automatically collected and analyzed. Using machine learning and predictive analytics, it is possible to automatically predict when an asset’s condition becomes critical and automatically create condition-based work orders before the asset becomes deficient and downtimes occur. The EAM software can provide information about which tools or replacement parts are required while scheduling a free maintenance technician to carry out the replacement.

Through software access on various devices – such as maintenance workstations, tablets and smartphones – the maintenance planner can track and monitor their work order as it is being carried out. An EAM software that can be used on any device from anywhere is an important part of the digitalization process and is essential for providing oversight and transparency of the assets life cycle and the connected maintenance operations.

Want to learn more about how EAM solutions from Aptean can help your business? Read our EAM guide or contact us today to chat with one of our experts and schedule a demo.

Ready to Start Transforming Your Business?

We’ve got the specialized EAM solutions you need to conquer your industry challenges.