Aptean EAM Case Study: Sterling Steel Company

Aptean EAM Case Study: Sterling Steel Company

Aptean EAM Case Study: Sterling Steel Company

Apr 28, 2025

Headline

- Sterling Steel Company Streamlines Operations With Aptean EAM

Sterling Steel has deep roots in Northern Illinois. Established in 1879 as Northwestern Steel & Wire, the company changed its name in 2002 to Sterling Steel Company, LLC when Leggett & Platt purchased a portion of it. The Rod Mill, built in 1952 and having been renovated over the years to improve operational efficiency, boasts finishing speeds of over 19,500 feet per minute and enables the facility to produce an average of 500,000 tons of steel rods annually.

The Challenge

Sterling Steel was using two disparate, outdated enterprise asset management system (EAM) systems. Having two siloed solutions created some challenges for the company, including:

Data extraction: Data had to be extracted via Microsoft Access and combined to create reports. This required onsite personnel to have programming skills and dedicated time to keep reports functioning properly amid routine IT system updates.

Independent servers: Each application had its own servers. In-house support for both systems and recurring annual support fees became unmanageable. The ongoing costs of supporting two systems were approaching an unsustainable level and upper management questioned the value of maintaining the two solutions.

System support and security concerns: Time that should have been allotted for advancing asset management was diverted to system maintenance. Sterling Steel’s parent company decided that for security reasons all IT departments across the organization should fall under one umbrella. In order to comply with the guidelines of the parent company’s IT department, Sterling Steel learned that the server for the second system was no longer supported, which made it vulnerable to attacks.

The Solution

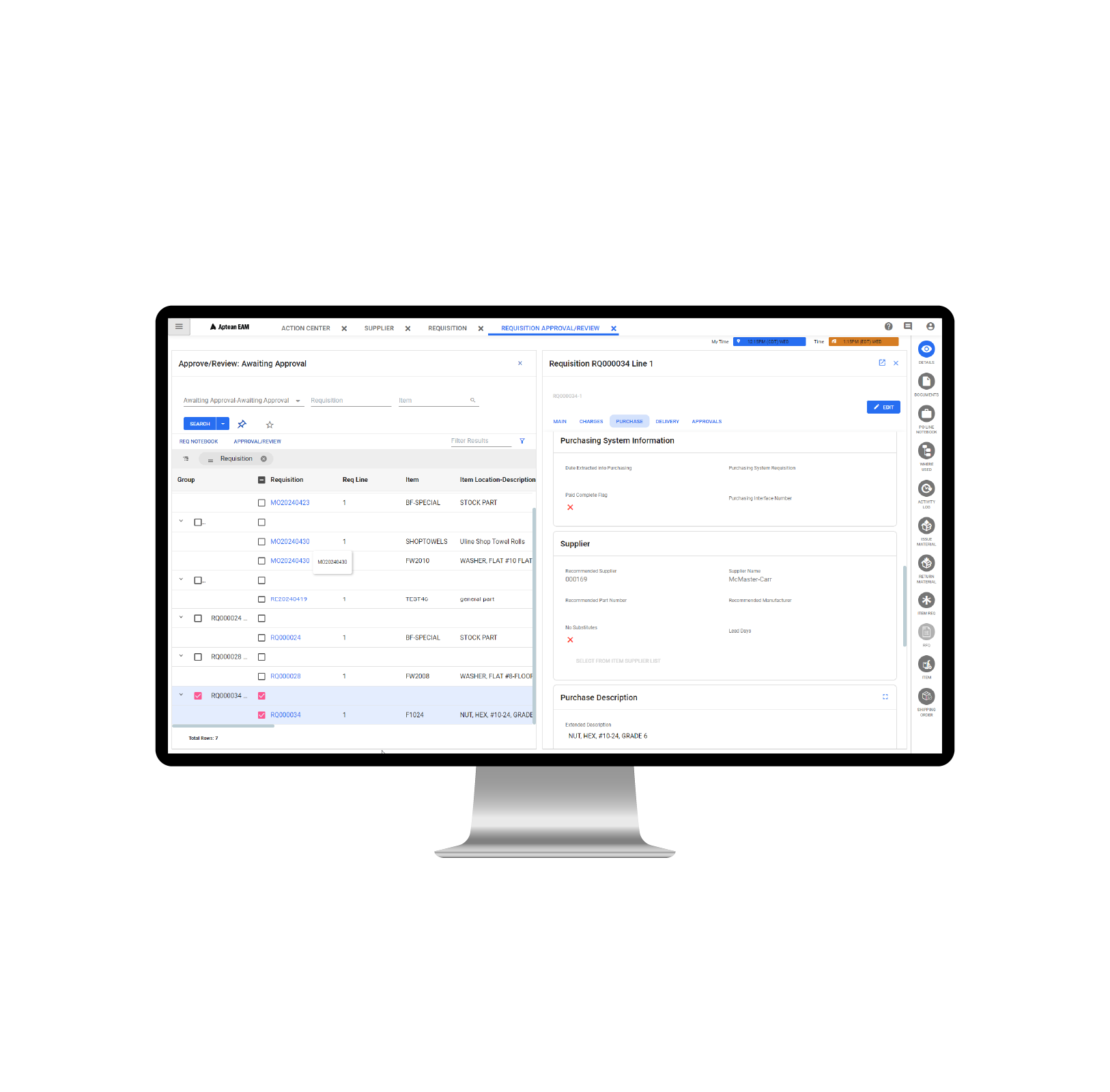

One of the EAM systems Sterling Steel had been using was Aptean EAM and had already begun to consider upgrading to the most current version. It was vital for the craftsmen to verify and understand the health of the assets to make sure the equipment can do the work required. Inspection activities allow the maintenance team to understand when assets are beginning to show signs of decreased functionality. Initially, the second asset management system provided the routes the craftsmen followed in order to understand the condition of the equipment. The Aptean EAM inspection module replaced the functionality of that system. Following demonstrations, Sterling Steel determined that upgrading to the current version of Aptean EAM would enable migration to a single solution, streamlining processes and reducing capital expenditures.

The Results

An informal analysis concluded that Sterling Steel reduced its annual maintenance expense by approximately $70,000 a year, and consolidating to a single server also reduced IT support costs. The redundant system was retired eight months after the Aptean EAM upgrade. Sterling Steel achieved the following:

Annual maintenance fee savings of approximately $70,000 a year

Less manpower required to maintain two systems

Saved almost 400 boxes of paper annually for an approximate cost savings of $20,000 a year

The inspection and analytics capabilities within Aptean EAM allow technicians to work more effectively. Craftsmen are self-directed using these tools, empowering them and giving them more ownership over their work. They also have more direct input about the health of the assets. Personalized reporting is available for each technician so they can see their individual contributions. Technicians download inspection routes to the tablets, perform the inspections and upload the results, as well as complete the work orders and charge time as required, which is new to Sterling Steel.

Using Aptean EAM for regular equipment inspections and calibrations enforces procedure adherence, critical data collection and consistent incident documentation. The tools help Sterling Steel spot issues before causing downtime, mitigate risk and ensure that production delivers a quality product in a safe, consistent and reliable manner.

It’s Time To Eliminate Downtime for Good

In an industry where uptime, compliance and worker safety are non-negotiable, the burden of managing outdated asset management systems can be overwhelming. You deserve a more innovative solution, one that is built specifically for the demands of metals and heavy industrial manufacturing. Aptean EAM is that solution—giving you the freedom from manual tasks, automating preventive maintenance and empowering technicians with real-time tools to keep equipment in peak condition.

With flexible inspection routes, mobile access for field teams and analytics that highlight inefficiencies before they lead to breakdowns, Aptean’s enterprise asset management software helps you enhance equipment reliability and minimize costly downtime. Whether you’re managing a single plant or an enterprise-wide operation, our solution gives you the control and insights you need to make smarter decisions—every shift, every day, instilling you with confidence and more control.

Even better, you’re not alone on this journey. With Aptean, you're backed by our in-house experts who understand your industry inside out. From implementation to optimization, we’re with you every step of the way—helping you configure the tools that make the most significant impact on your operation, providing you with the reassurance and confidence you need in your decision.

If you’re ready to replace outdated systems and run a safer, more efficient operation like Sterling Steel, get in touch with our team or schedule a personalized demo.

Ready to Start Transforming Your Business?

We’ve got the specialized EAM solutions you need to conquer your industry challenges.