Featured in this post

The C Suite Checklist: How to Answer the Top 5 Questions About Your Fleet's Operational and Financial Performance

The C Suite Checklist: How to Answer the Top 5 Questions About Your Fleet's Operational and Financial Performance

Oct 26, 2021

Jim Endres | Regional Account Director

Jim Endres | Regional Account Director

You’ve been working as the CEO of a successful fleet company for years. You love your job, but you hate the paperwork that accompanies it. You also know that logistics companies have entered a new era—speed in delivery isn’t enough anymore. The customer is king, and your fleet must be in the right place at the right time with the right product mix.

Delivery excellence is now the biggest metric that will set your company apart from the competition, and competition is brutal. You know that fleet metrics are important; it helps you and your fleet managers know where to invest money to improve vehicle efficiency.

If the owner of the company stopped you in the hallway tomorrow and asked you how the fleet was performing, would you have a definitive answer for him? Or would you stammer, hesitate, and tell him you’d get back to him with some numbers once you ran some reports?

None of us like to be caught out and questioned about our job, but if you’re a CEO or CFO of a fleet, there are certain metrics that should always be top of mind for you. Do you know what those metrics are?

And further, would you be able to cite key performance indicators (KPIs) about your fleet at a moment’s notice?

Fear not—we’ve got you covered. We’ve got the definitive list of what metrics modern fleets need to be tracking, and we’ve got the tools to help you answer any questions that might come your way—no spreadsheets needed.

1. Cost per Mile

According to the latest stats from ATRI, the average cost per mile for trucking companies went down dramatically in 2020 to $1.63 per mile. For private fleets, that number is higher—stats from NPTC put the cost per mile at $2.90. Of course, that doesn’t account for the fact that many fleets are driving more miles with smaller loads.

Do you know how to calculate the true cost per mile for your fleet? If you tried to do it by hand, it would take hours, maybe even days. You’d have to know all vehicle-based and driver-based costs down to the penny, and then would have to calculate that out between every driver and every truck in the fleet. Even if you run a small- to medium-size logistics enterprise, those numbers would get unmanageable very quickly.

If you’re still using manual methods to plan your fleet’s routes, you’re throwing away money. If you had route optimization software, calculating an aggregate of your fleet’s cost per mile data would be a breeze. And if you use that data to shave miles off the routes that each truck drives, it translates into significant savings for the business.

By using routing and scheduling software, the average fleet owner saves somewhere between 10-30% per year. To put it into monetary savings, if one truck in your fleet drove 75,000 miles this year, at the current rate of $1.63, it costs you $122,250 to keep that truck operating. Take an average of 15% off that number. You just saved almost $20,000—on one truck. For private fleets, you’d save close to $185,000.

With routing software, you have the ability to drill down, look at driver performance and get a better picture of how to drive these costs even lower. For instance, nobody can control variable costs like fuel. But you can control how your drivers act behind the wheel. If they are idling for long periods or using excessive speed you easily identify the drivers who are burning more fuel. Then you can use that data as part of the driver scorecard and it becomes a coaching tool.

2. Customer Service

It doesn’t matter what your fleet delivers—whether you deliver baked goods or furniture, your customers expect more than just a random delivery window. They also want to be able to choose a delivery time that works for their schedule, not for yours. What if you have a client that specifies a delivery at 11:00 a.m. so that the warehouse team will be done with their administrative tasks? Or perhaps you have a client that needs their items delivered after the store closes to avoid any disruption on the floor.

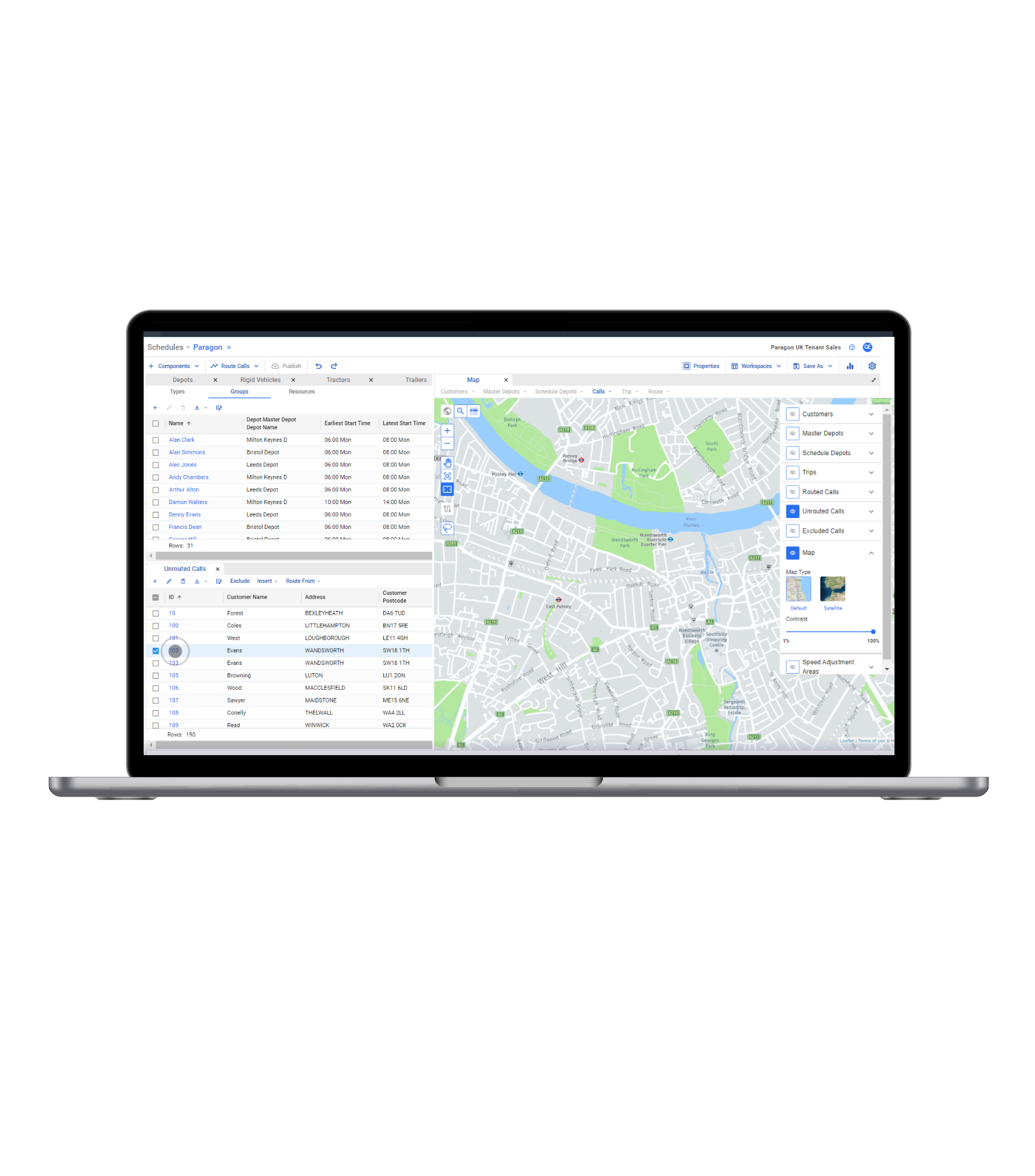

Managing those parameters manually would be problematic and time-consuming. With advanced routing and planning software, not only can you keep track of the various customer details, but you do it in the most efficient way possible. In addition, your team can manage increasingly complex delivery patterns, as the route planning algorithms ensure high levels of service remain consistent.

You also streamline customer communications by automating delivery information. Your clients will know exactly where their deliveries are; and if there is a complex issue that needs to be addressed, your service team can call the customer immediately and help with resolution. This leaves your drivers free to move on to the next stop, rather than having to placate an angry customer.

3. OTIF

OTIF, or on-time, in full, seems like a straightforward metric; it measures the speed, accuracy, and capacity of your fleet to fulfill customer orders. It’s actually two metrics in one. But how do you get an accurate picture of how your team is performing in these areas? It’s probably a little different for every company, but the concept originated from retail giant Walmart in 2017. Walmart began evaluating their retail suppliers by their ability to deliver orders on time. They then proceeded to levy fines on those suppliers that didn’t make the cut.

While this metric is relatively new in the logistics world, it is one of the biggest metrics that many major retailers now use. And there’s more to it—Walmart not only issues fines to tardy suppliers, but they also penalize shippers that miss parts of the delivery order by charging them 3% of the cost of each item missed. So not only is OTIF important to maintain good customer relationships, but it can be an expensive proposition if your team keeps missing OTIF targets. Look at OTIF as a barometer of your company’s abilities. If your team is not consistently meeting targets at 80% or higher, it’s time to do an analysis and figure out why. Conversely, concentrating on driving up the score at the expense of other metrics, like driver satisfaction, will lead to inefficiencies in other areas.

What’s the solution? Real-time route optimization solutions have the tools to help you plan, analyze, create, and deliver the most profitable route plans and strategies for every customer. Think about it this way—if your driver misses a delivery window and it’s your fault, who bears the costs of redelivery? YOU. By using algorithms and GPS, your fleet manager actively monitors every scheduled delivery and can report back if there are any issues. With standard and custom reports available to you daily, you’ll know exactly how your team is doing at every minute and can fix issues proactively.

4. Continuous Improvements / Driver Debrief

At the risk of being repetitive, your customers’ expectations are astronomical. They not only expect your drivers to deliver on-time, in full, but they also expect them to follow their specific compliance standards.

In the not-too-distant past, a successful logistics company was one where the drivers came back with an empty truck and there were no active customer complaints. Now, you need to always keep tabs on your drivers. You know that fleet management software can help with route optimization, but did you know that it can help with driver performance, as well?

Let’s say that you notice that one of your drivers has gone off-route. You get an alert, letting you know that this deviation might make them late for their scheduled stop. The driver might well have a valid reason for the change. Perhaps the originally scheduled morning customer prefers an afternoon window, so your driver bypassed their store to honor that preference. It may simply be that there was an accident or construction on the initial route. Either way, you will have the information you need to address issues immediately.

Once the driver returns and you have a quick debrief, you then update the system to reflect the new information, assuring that future routes which include that stop will have that data. Before the shift ends, a simple color-coding system lets the driver know whether they can go home immediately after the shift (green) or needs to return to the warehouse to have a debrief (red). Because you always want to improve routing and delivery, the debrief is a great opportunity to either incorporate better route information or to gently guide the driver toward better practices.

5. Driver Score Carding and Incentivization

With the right routing and scheduling software, you will get a driver activity report daily. You can customize it to best match what metrics you need. You can pull the information from multiple dashboards, depending on what area you’d like to focus.

For example, if you want to get current numbers on driver safety records, you might pull data on excessive speeding or harsh braking events. If you want to know about excess hours for payroll, you can look at hours idling versus active hours. You can get information on any aspect of telematics, including:

Miles driven

Time driven

Planned vs. actual route

Fuel consumed

This generates a driver scorecard that gives you and your fleet manager a data-driven analysis of every driver’s performance. Maybe you want to improve delivery performance. By linking tracking data and information produced from the driver debriefs, you have the numbers you need to make better delivery routes and get measurable, achievable improvements. To give the drivers further incentive, you can post the stats from the top performers and give out rewards. And you can assist lower-performing drivers by giving them easier routes to complete or giving them additional training.

Not sold yet? Here’s another fun fact about routing software. The turnaround for ROI can be as fast as the first day. The software works on a continuous improvement loop, which essentially means that any information gathered from your drivers, customers and telematics systems goes back into the platform. The system learns as you update, so that route plans consistently get better and more efficient as time goes on.

Learn more about routing and scheduling software and what benefits you can gain. Talk to one of our experts today.

Tried the Product Tour and Ready to Get Into Gear?

Book your full demo with our team today to see how our advanced routing software can help you accelerate performance.