Featured in this post

Your Step-By-Step Guide to a Reliable Food Product Recall Procedure

Your Step-By-Step Guide to a Reliable Food Product Recall Procedure

Blog Post

Key Takeaways

A strong food product recall procedure requires preparation, clear roles and the right tools. Focus on these core steps:

Know the regulations: Stay compliant with FDA, FSIS, FSA and EU requirements to avoid penalties and reputational damage.

Train and prepare your team: Provide ongoing education, practise mock recalls and ensure everyone knows their role.

Use technology for traceability: Food ERP systems give you end-to-end visibility and speed when every second matters.

Build and document your recall plan: Define triggers, responsibilities and communication protocols in advance.

Act fast during recalls: Track distribution, identify affected products, remove them safely and notify stakeholders.

Learn and improve: Investigate root causes, document the process and refine your strategy with regular reviews.

If the mere phrase “product recall” sends a cold chill down your spine, you’re not alone. Food and beverage professionals across the globe share your concern—and for good reason.

Just look at the recent recall from Kraft Heinz, which resulted in in approximately 367,000 lbs. of turkey bacon products being pulled from shelves in the U.S. due to possible listeria contamination. In a matter of hours, the story made headlines, regulatory agencies got involved, and consumer trust suffered as products made their way back to distribution centres. If it can happen to a major brand like Kraft Heinz, no business is immune.

Recalls of this magnitude only occur once or twice a year, but even that is too frequent. And smaller-scale recalls are alarmingly common. The World Health Organization reports more than 600 million cases of foodborne illness every year worldwide—420,000 of which result in death. This means that your organisation must take safeguarding your consumers and protecting your brand seriously. And with the average food recall procedure costing millions of pounds, the stakes couldn’t be higher.

Really, though, there’s no reason to fear or feel threatened—assuming your operations are fully supported by a robust incident prevention program and detailed food product recall procedure, that is. But what exactly does it take to prepare for these events, and how can a purpose-built enterprise resource planning (ERP) solution help you enhance your strategy and maintain better food safety overall?

We’re here to fill you in, so let’s begin with the basics.

Be Prepared Before the Recall Hits

A reliable food product recall procedure doesn’t start the day something goes wrong. It starts much earlier—with groundwork that ensures your teams are trained, your systems are ready, and your response is compliant and fast. Because when a recall hits, the last thing you want is to be caught scrambling. Here's what you need to have in place before the pressure’s on.

Know the Legal and Regulatory Requirements

Before you can build a sound food recall process, you need to understand exactly what’s required of your organisation and which bodies are involved.

In the U.S., the Food and Drug Administration (FDA) has fairly extensive guidance on the food recall procedure, including identification of its depth and issuance of both an official letter to notify the public and periodic status reports. Of note, the Food Safety Modernization Act of 2011 (FSMA) does give the FDA authority to make a recall mandatory if the company responsible for a food safety emergency does not take action on its own. The U.S. Department of Agriculture’s Food Safety and Inspection Service (FSIS) handles recalls for meat, poultry and processed egg products. It follows FDA rules but has additional requirements.

In Canada, the Canadian Food Inspection Agency (CFIA) oversees food product recalls. While some are conducted voluntarily, the Minister of Health can order a recall if the company refuses to act, and all food businesses are required by law to have a documented recall procedure.

In the UK, the Food Standards Agency (FSA) provides comprehensive instructions for the recall procedure in the food industry, from initial investigation and risk assessment to notifying stakeholders and disposing of the affected products. Their step-by-step guidance helps ensure businesses meet their legal obligations and protect public health.

In the EU, the General Food Law Regulation provides four measures—the establishment of the Rapid Alert System for Food and Feed (RASFF); the creation of the Standing Committee on Plants, Animals, Food and Feed (PAFF Committee); adoption of emergency measures; and, most importantly, a general plan for crisis management.

If you fall short of food traceability regulations, the cost isn’t just financial—it can be legal and reputational. Non-compliance could trigger enforcement actions like hefty fines, product seizures, licence revocation or facility suspension, alongside a loss of consumer trust that’s difficult to win back. You don’t want your organisation making headlines for all the wrong reasons.

As the saying goes, “knowledge is power.” So use checklists or digital dashboards to stay aligned with regulatory shifts and make compliance a non-negotiable part of your food safety strategy and food recall process.

Train Your Teams Before the Worst Happens

A well-trained and diligent team of professionals is one of the best possible safeguards against food safety emergencies in the food industry. They need to be well-educated on proper procedures, including sanitation processes, allergen management, use of safety gear, and documentation of incidents and your business’s specialised internal processes.

Keep in mind, too, that as circumstances change—novel products are introduced to your line up, equipment is replaced or new systems are implemented—additional training should be provided. Everyone must be up to speed in order to minimise the chances that you’ll need to issue a recall, and good instructions should never be foregone for the sake of convenience.

It’s also a smart move to practise recall procedure in the food industry and conduct regular internal food safety audits so that your staff are aware of what it’s like to jump into action and investigate an issue. Gaining an understanding of the challenges involved and how it feels to act with confidence and agility in the moment will serve them well should a real emergency occur.

Use Technology To Strengthen Traceability and Speed

Putting in place the right food traceability software is another critically important step in optimising your approach to food safety and maximising recall readiness. That’s because cross-functional, digital platforms like specialised food enterprise resource planning (ERP) systems are packed with features that will have you fully equipped for the tasks at hand.

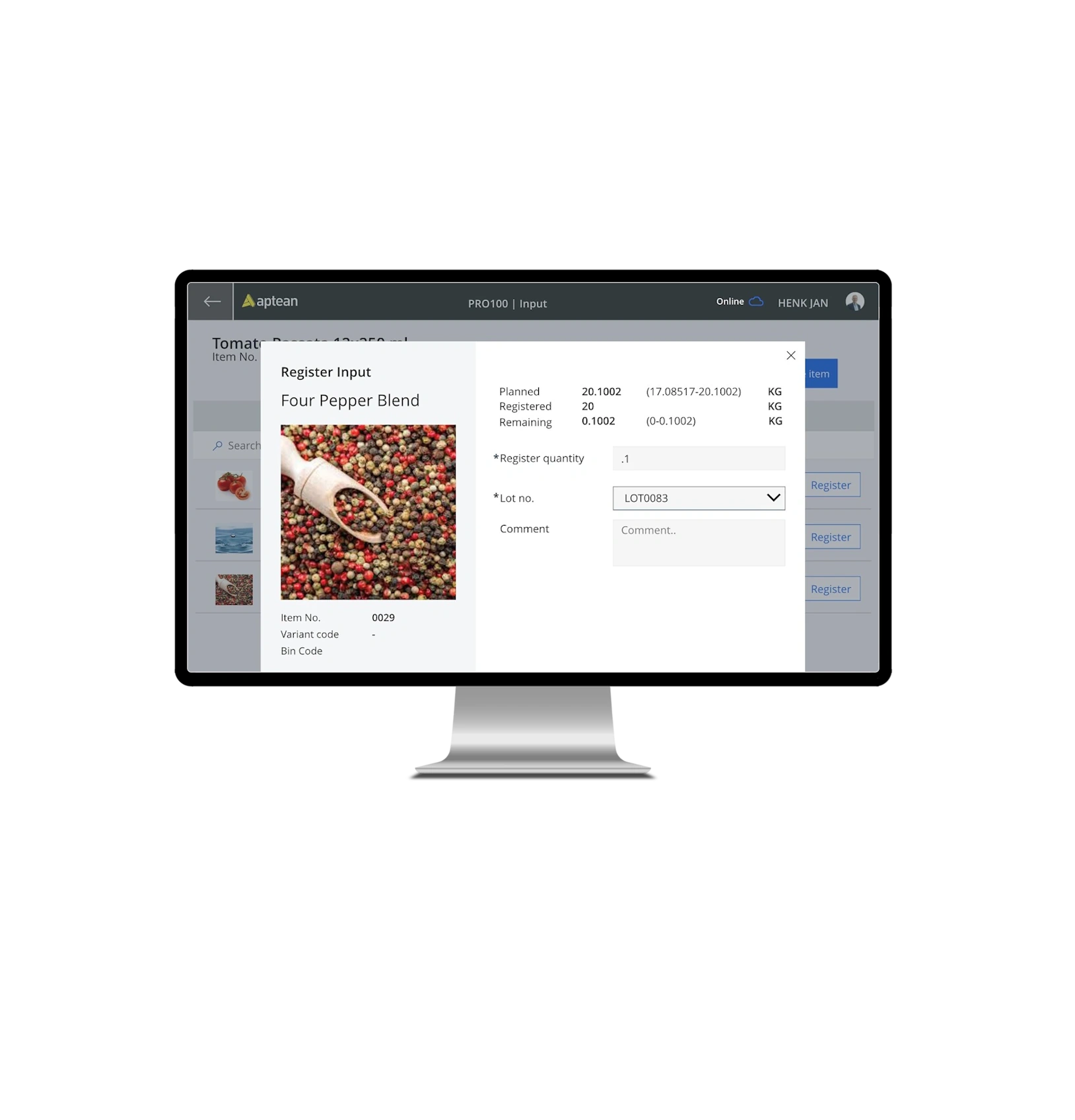

For example, modern food ERP systems are equipped with features that make maintaining complete bi-directional tracking of raw materials and finished goods a much simpler matter. By logging all ingredient and product data at each point in the supply chain—both outside and inside your facilities—you’ll have visibility and immediate access to a digital record of the path each lot and individual item takes.

An efficient food safety and traceability system deploys regular alerts to ensure all safety and sanitation checks occur reliably—crucial in busy food factories with high-volume production runs—and supports allergen management by flagging high-risk ingredients in recipes.

Build a Food Recall Procedure You Can Count On

Once your foundation is in place—regulatory knowledge, team training and the right technology—you’re ready to build the core of your food product recall procedure. This is your go-to plan when something goes wrong. It needs to be detailed, documented and practised. And most importantly, it should leave zero room for delay or confusion when every second matters.

A strong recall procedure in the food industry plan includes clear step-by-step actions for identifying the problem, assessing risk, notifying stakeholders and removing the affected product from the market. But that’s just the beginning. Here’s what your food recall process should include—and how each step supports a fast, compliant response.

1. Appoint a Recall Coordinator and Team

Start by forming a recall team with key personnel from departments like quality, operations, legal, product development and communications. Select team members who know your products well, can handle pressure and work well with others. Clearly outline each person’s role and set up a reporting structure so everyone knows who to contact during a recall.

Then, choose a recall coordinator to lead the team. This person should have the authority to make quick decisions and a solid understanding of your supply chain, safety regulations and products. It's best to look for someone experienced with outstanding leadership, strong communication and crisis management skills. They’ll manage the food recall process and act as the main point of contact with company leadership.

To keep things running smoothly, assign backups for each role and maintain a contact list with up-to-date phone numbers and emails. When a recall happens, clear roles and fast communication help you act quickly and effectively according to your food recall procedure.

2. Develop a Detailed Recall Plan Document

Your recall plan should clearly outline what triggers the process, how to respond and who’s responsible at every step—from internal escalation and communication protocols to consumer notification procedures and regulatory reporting timelines. In the U.S., use a simple decision tree to help classify the recall type—Class I (serious health risk), Class II (temporary risk) or Class III (non-health-related). In the UK and EU, recalls are flagged by regulatory authorities with urgency and risk levels.

Next, prepare pre-drafted recall notice templates that feature product images, lot numbers, UPCs and instructions for consumers. You can store this information with your food recall procedure in your ERP system alongside data on suppliers, production batches and customer records in one place—so your team can act quickly. This saves time and ensures consistency during the food recall procedure.

It's better to include details on communication channels—such as email, phone, press releases, social media—and including multilingual options for global operations. Keep the plan easily accessible, both digital and in print, with version control. Review and update it annually, or whenever your product lines, suppliers or regulatory environment changes.

3. Track Product Distribution in Detail

If you can't track where your products went, you can't recall them efficiently. That’s why a cornerstone of any effective recall procedure in the food industry is a robust distribution tracking system. Your records should include batch or lot numbers, shipping dates, delivery locations and quantities.

Ideally, fully integrated ERP and transport solutions provide you end-to-end visibility, from raw materials and inventory to retail shelves and foodservice outlets, so you can easily track shipment history to trace exactly where each batch was sent and who received it. That level of detail helps you act fast, notifying only the affected parties and minimising disruption of unaffected customers or products.

Make sure your tracking system also captures information from third-party logistics partners, co-packers and distributors. These links in the chain are often overlooked—but if you’re missing data from a specific node, your food recall process may spiral. Accuracy here can be the difference between a targeted withdrawal or a public nightmare, and a well-executed food product recall procedure prevents that.

4. Identify Affected Products Quickly

Before you can remove product, you need to know exactly what’s at risk. That means pinpointing affected lots, ingredients and even co-manufacturers using detailed records and tech-enabled traceability tools.

Use backward and forward traceability to connect raw ingredients with finished goods and end customers. This visibility is essential not just for pulling product, but for understanding exposure—and answering regulators when they ask, "What went wrong?".

Don’t rely on memory or spreadsheets. Your traceability system should allow your recall coordinator to isolate affected inventory with a few clicks. With features like lot and batch traceability, a great ERP system enables the identification of the scope of contamination and a rapid response. The more precise your food product recall procedure, the fewer products you waste and the faster you restore business continuity.

5. Execute Product Removal and Disposal

Once you’ve identified the impacted products, you need to act fast to get them off shelves, out of warehouses and away from consumers. That requires detailed instructions for logistics, removal and safe disposal.

Your plan should include recall initiation letters for downstream partners, a process for product returns and clear protocols for documenting and verifying product destruction. Build in checkpoints to ensure every unit is accounted for. And, if you already have a food ERP in place, this can help you coordinate product withdrawal by integrating logistics, inventory and partner data—ensuring faster execution and real-time visibility into the status of removals.

It’s also important to work with third-party logistics providers ahead of time. Understand their recall readiness and rehearse coordinated removal procedures. In other words, don’t assume your partners will know what to do unless you’ve already shown them.

6. Notify Customers, Partners and Regulators

You’re required to inform your local regulatory authority about any recall that impacts consumer health—but that’s only one piece of the puzzle. Customers, supply chain partners and even internal stakeholders need fast, clear communication.

Now is the time for you to customise your pre-written recall notice templates. Make sure they’re ready to send and include all the necessary details: affected product info, what actions recipients should take and who to contact for follow-up questions. If regulators have specific forms or portals (like the FDA's safety reporting portal or the FSA's online notification tools), ensure your team knows how to use them. For instance, FSA guidance strictly emphasises the importance of acting swiftly to report food incidents and withdrawing the unsafe product from the market.

With centralised contact data, your food and beverage ERP system can help you send alerts across your network, enabling you to quickly reach the right people with accurate, consistent messaging. Don't delay communication until you "know everything"—act with an abundance of caution. Notify early with the facts you have and issue updates as needed. Transparency shows you're in control and committed to food safety—a message every stakeholder wants to hear in a well-handled food recall procedure.

7. Isolate the Source and Conduct Root Cause Analysis

Once the immediate threat is contained, it’s time to investigate the cause. Your traceability tools should help you not only identify where the product went but also why and where the issue originated—whether it was a supplier defect, production error, packaging oversight or something else entirely.

Map the path of the product backward through your supply chain to isolate the root cause. Was it a specific ingredient? A machine failure? A mislabelled batch? Document every step and decision so you're ready if regulators ask for a timeline.

Use this analysis to support corrective and preventive actions. That could include supplier reviews, process changes or updated training protocols. A food industry recall procedure isn’t truly complete until you've closed the loop on the cause and reduced or eliminated the chance of it happening again.

8. Document and Review the Process

Now the dust has settled, step back and evaluate your response. Start by documenting every action taken—from the first alert to the final product disposal. This includes communications, traceability reports, meeting minutes and regulator correspondence. Then hold a debrief to evaluate your response. What went smoothly? Where were the bottlenecks? Honest feedback from all departments can reveal valuable insights to strengthen your process.

But don’t stop there—schedule unannounced mock recalls. Remember, these aren’t just checkbox exercises; they’re your chance to test real-world readiness. Use them to identify communication gaps, record-keeping issues or confusion regarding roles. Document what worked, what didn’t and how you’ll improve next time.

The most effective recall plans aren’t just written—they’re practised. Make mock recall training a regular calendar item and treat simulations with the seriousness of a real event. When everyone knows their role by heart, your team can move faster, avoid costly errors and give regulators and customers confidence that you’re fully in control.

Trust Aptean To Power Your Food Recall Procedure With Precision

By now, you’ve seen how a proactive, step-by-step approach makes all the difference when it comes to recall readiness. From understanding regulatory requirements and training your employees to establishing communication procedures and assembling the right team—each step strengthens your ability to act fast and protect your brand when every second matters.

But having a plan is one thing. Having the right technology to carry it out? That’s where Aptean gives you the edge.

Aptean Food & Beverage ERP is built specifically for food and beverage companies—no generic workarounds, no clunky add-ons. Just purpose-built tools that help you maintain total visibility from raw ingredients to final product, all while staying compliant with evolving global regulations. With built-in lot traceability, allergen tracking and recall automation, you’re equipped to contain issues quickly and keep stakeholders informed.

For example, our specialised food ERP expedites the process of isolating the source of contaminations and issuance of necessary communications to affected parties. That lets your highly qualified personnel concentrate on other critical steps like organising withdrawal efforts and properly documenting the incident.

Our cloud-based platform also gives you real-time access to mission-critical data anytime, anywhere—supporting faster decisions, tighter collaboration and greater operational resilience. And because we’re cloud-first and building artificial intelligence (AI) into everything we do, you can also tap into sophisticated forecasting, predictive insights and continuous optimisation across your supply chain.

In short, we don’t just help you respond to recalls—we help you stay ahead of them.

Want to see it all in action? Take a self-guided product tour or request a personalised demo of Aptean Food & Beverage ERP today.

Get In Touch Today To Speak With an Expert in Your Industry

To grow your business, you need a food ERP built specifically for your industry challenges. We're ready to help—reach out today and we'll help you find the right solution.

Jack Payne | Vice President, Product Management & Solutions Consulting

Jack Payne | Vice President, Product Management & Solutions Consulting